When industrial dust collection equipment is integrated into complete systems, they maximize the removal of airborne contaminants from polluted airstreams prior to atmospheric discharge. Where feasible, they allow the return of cleaned air back into the manufacturing facility.

The type of industrial dust collector you need, as well as the final ventilation system design, depends on several “key” factors. These include the collected particulates’ physical and chemical composition, process exhaust conditions of temperature and moisture, and both local and federal regulations.

“At SysTech Design, we select and market components that adhere to best practices, maximize efficiency, constructed for longevity, and are in compliance to published Standards and Codes.” – John Conley 1986

Importance of Industrial Dust Collection Systems

Effective industrial dust collection system designs provide:

- Employee protection from the harmful effects of air pollutants in the form of dust, fumes, and mists.

- Facilities that are compliant with safety, occupational health and air emission regulations.

- Protection for the local environment from air pollutants generated by manufacturing processes.

- Personnel and facility safety in the form of explosion protection when handling combustible dust.

- Attenuation of excessive noise, either as personnel hearing protection or adherence to sound levels at the property line.

Industrial Dust Collection Systems Walkthrough, Inspection or Troubleshooting

Industrial dust collection systems are made up of important pieces of equipment that need to be operating as designed for efficient operation. From the dust collector type, filter media selection, fan performance and placement, dampers, silencers, duct, and capture hoods all need to be “matched” to maximize collection efficiency. Walkthroughs will point out design errors or wear points in the system and troubleshooting will determine the extent of repairs needed. If access is not possible, virtual inspections are an option.

Types of Industrial Dust Collection Systems

There are two key areas we focus on when reviewing a new system layout. First, the geometry and chemistry of particulate in the air stream which determines the way we configure and select components. Clean air system flow control components such as multibladed dampers on the “dirty side” can no longer be used as they would gum up or fail prematurely. The second key factor is keeping particulate in suspension after it is collected and effectively conveying it to the filtration device. Should equipment slowly fail or breakdown, particulate settling in the duct creates potential duct collapse, leaks in the duct, fire and explosion potential, additional static pressure loses with increases in fan horsepower, fan wheel abrasion, and imbalance.

Our systems approach is divided into two types:

Ducted Pollution Control Systems – These systems are often termed central systems meaning the pollution control device or dust collector is located away from the process collection point and a duct system conveys the material to the air cleaning device. It is critical when evaluating systems that all the components included are of equal quality and value. The major components would include the dust or mist collector, capture hood (s), conveying duct, flex connector (s), fan damper, and HEPA filter assemblies. Also, duct layout, start-up and commissioning services, and controls need to be closely evaluated.

Self-Contained Dust Collectors – Self-contained dust collectors are a “complete” system by design, in that they include all the items included in a ducted system, but without the duct. These would include smaller cartridge and envelope bag collectors, portable dust collectors, downdraft benches, downdraft tables, portable equipment, and environmental control booths.

SysTech has developed quite a few systems since 1985. We configure industrial dust and fume collection systems using quality components and the proper materials of construction. Examples are:

Dust Collection System Design Considerations

Dust, fume, and mist collection system design is about:

- Maintaining airflow thru the system to minimize particulate and material deposition

- Minimizing noise levels from components

- Minimizing the pressure loses thru the system with proper duct and fitting configuration

- Minimizing horsepower requirements

- Maximizing capture with hoods with correct airflow

- Maintaining the integrity of duct and components by selection of proper materials of construction

Typical Dust Collection System Components

Dust Collectors – Dust collector designs are available to handle most dust encountered. Whether bags, cartridges, pleated bags, blanket media, or box filters, maximizing collection efficiency with filter media longevity is the goal. Understanding of the materials being collected, before equipment selection, will ensure these criteria are met.

Explosion Protection – Where there is combustible dust, required explosion protection in the form of explosion vents, explosion isolation flap valves, and explosion suppression systems that are compliant to NFPA Standards and local Codes.

Industrial Dampers and Louvers – Industrial dampers may be used to adjust the airflow on the clean air side of the pollution control device. Materials of construction will vary depending upon airstream constituents.

Industrial Duct Systems – Industrial duct systems are sized and constructed for the materials being conveyed. Duct, elbows, and fitting options include carbon steel, galvanized steel, stainless steel, FRP, and PVC as options.

Flexible Connectors – Duct connected to a fan or blower requires a flex connector for vibration isolation. If noise is an issue, these connectors can be fitted with acoustic treatment to prevent breakout noise from the fan.

Industrial Exhausters – An industrial exhauster conveys the dust or mist with maximum efficiency while meeting the design performance requirements. Materials of construction vary to match the material conveyed and the airstream chemistry.

Fan Silencers – Fan silencers are selected to attenuate noise from either the fan inlet or discharge, which may or may not be ducted back into the facility. Silencers on the fan inlet prevent noise radiating back thru the collection system into the plant.

Electrical Controls – Electrical Control packages are offered to monitor fan motor speed, dust collector pulse cleaning, and explosion protection devices along with standard start-stop switches and disconnects.

Dust Collector Technologies

They are many air cleaning technologies available for dust and mist filtration. Selection is based on the characteristics of the particulate or mist such as chemistry or abrasiveness, temperature, amount of material collected, explosivity of the materials, amount of maintenance the client can assign to the air cleaner, and location of the air cleaner in the facility. The major dust collector technology options would include:

Cartridge Dust Collectors

Cartridge dust collectors are the preferred means for dust collection because of their initial efficiency, minimal space envelope, and ease of maintenance. That said, baghouses are still required in those process areas where material loadings and material characteristics require their use. When cartridge-style units are implemented, Donaldson® Torit® advanced technology cartridge dust collectors and filtration media provide effective solutions for managing a variety of industrial dust control issues including toxic, explosive, and potent compounds. Both their Downflo® Evolution (DFE) Collector and Downflo® Oval (DFO) Dust Collector set the standard for cartridge dust collection.

Cartridge dust collectors are the preferred means for dust collection because of their initial efficiency, minimal space envelope, and ease of maintenance. That said, baghouses are still required in those process areas where material loadings and material characteristics require their use. When cartridge-style units are implemented, Donaldson® Torit® advanced technology cartridge dust collectors and filtration media provide effective solutions for managing a variety of industrial dust control issues including toxic, explosive, and potent compounds. Both their Downflo® Evolution (DFE) Collector and Downflo® Oval (DFO) Dust Collector set the standard for cartridge dust collection.

- Powered by patented Ultra-Web® nanofiber filtration technology

- Provide cleaner air with up to 25% more filtration capacity than other collectors

- Dust collection filters last up to two times longer

- Provide significant cost savings and optimal service

Donaldson® filtration research and development has led to cartridge dust collectors that solve most industrial dust and particulate challenges in a variety of facilities such as:

- Chemical

- Woodworking

- Pharmaceutical

- Food Processing

- Metalworking

Potent Compound Dust Collector

Accidental atmospheric release of and worker exposure to potent compounds is a major concern in the pharmaceutical industry. Pharmaceutical materials containment is of utmost importance. Donaldson® Torit® Downflo® has set containment standards for pharmaceutical dust containment systems with:

Accidental atmospheric release of and worker exposure to potent compounds is a major concern in the pharmaceutical industry. Pharmaceutical materials containment is of utmost importance. Donaldson® Torit® Downflo® has set containment standards for pharmaceutical dust containment systems with:

- Filters and contains dust of low, intermediate, and potent toxicity

- Potent compound surrogate tested

- Features triple-sealed Bag-In/Bag-Out (BIBO) components at the filters

- Includes integrated HEPA BIBO chamber under negative pressure

- Variety of clean-change dust discharge options such as a continuous liner

Power Core® Dust Collectors

Dust collector applications and collection systems rely on a dust collector with filter media that has high-efficiency particulate removal with long filter life. Donaldson® Torit® with their Power Core® dust collector designs, couples Ultra-Web® filter media in unique pack symmetry with an enhanced filter cleaning system to address that need. The filtration media in each pack is configured in a corrugated flute structure allowing a straight-through airflow. A 60% reduction in filter size is gained over cylindrical cartridge filters. This is the recognized next generation in dust collector design. The filter packs significantly reduce the collector “box” size, change-out maintenance time/costs, and operation costs. The only thing not reduced is the interval between filter replacements.

Dust collector applications and collection systems rely on a dust collector with filter media that has high-efficiency particulate removal with long filter life. Donaldson® Torit® with their Power Core® dust collector designs, couples Ultra-Web® filter media in unique pack symmetry with an enhanced filter cleaning system to address that need. The filtration media in each pack is configured in a corrugated flute structure allowing a straight-through airflow. A 60% reduction in filter size is gained over cylindrical cartridge filters. This is the recognized next generation in dust collector design. The filter packs significantly reduce the collector “box” size, change-out maintenance time/costs, and operation costs. The only thing not reduced is the interval between filter replacements.

Donaldson DFE Dust Collector

Advancing technological has always been a Donaldson Company trademark. The Donaldson® Downflo® Evolution (DFE) dust collector series advances a new design package with fewer filters and a smaller footprint. It has an enhanced MaxPulse™ filter element cleaning system, triagonal shaped filter cartridges and their proven Ultra-Web® filter media. The DFE was designed to enhance filter cleaning, improve filtration capacity, increase filter life and reduce compressed air usage. This evolution is just another example of Donaldson’s commitment to provide the best dust collector design on the market.

Advancing technological has always been a Donaldson Company trademark. The Donaldson® Downflo® Evolution (DFE) dust collector series advances a new design package with fewer filters and a smaller footprint. It has an enhanced MaxPulse™ filter element cleaning system, triagonal shaped filter cartridges and their proven Ultra-Web® filter media. The DFE was designed to enhance filter cleaning, improve filtration capacity, increase filter life and reduce compressed air usage. This evolution is just another example of Donaldson’s commitment to provide the best dust collector design on the market.

Baghouse Dust Collector

Where required, the baghouse is the acceptable means to control those dust loadings made up of agglomerative or fibrous materials, concrete, limestone, and various melt shop applications to name a few. The availability of numerous filter bag materials allows effective filtration efficiency over a wide span of process dust applications. Donaldson® Torit® line of baghouse dust collectors features the Torit® RF Baghouse dust collectors, developed to handle large air volume and heavy dust loading encountered in process applications such as:

Where required, the baghouse is the acceptable means to control those dust loadings made up of agglomerative or fibrous materials, concrete, limestone, and various melt shop applications to name a few. The availability of numerous filter bag materials allows effective filtration efficiency over a wide span of process dust applications. Donaldson® Torit® line of baghouse dust collectors features the Torit® RF Baghouse dust collectors, developed to handle large air volume and heavy dust loading encountered in process applications such as:

- Food Processing

- Grain

- Cement

- Woodworking

- Chemical

The RF dust collector design as well as other Donaldson baghouse models have multiple filter media options based on particulate capture efficiency and airstream conditions. Need more airflow out of an existing collector? Consider the retrofit advantages using our pleated filter media.

Donaldson Torit DCE® Dalamatic® Dust Collector

The Donaldson Torit DCE® Dalamatic® Dust Collector is an auto-reverse jet dust collector suitable for continuous process applications that have high product loads. They are available in stand-alone units or as insertables into process streams. Available with Dura-Life Filter Media resulting in surface loading, high filtration efficiency, and 2 to 3 times normal bag life.

The Donaldson Torit DCE® Dalamatic® Dust Collector is an auto-reverse jet dust collector suitable for continuous process applications that have high product loads. They are available in stand-alone units or as insertables into process streams. Available with Dura-Life Filter Media resulting in surface loading, high filtration efficiency, and 2 to 3 times normal bag life.

Features include:

- Contiguous filtration of high dust concentrations

- The compressed air cleaning system

- Stand-alone or insertable configurations

- Downward airflow to minimizes re-entrainment

- Modular design means future capacity

- Horizontal bag removal

- Food contact Compliant configuration if using optional Helix Tubes

Silo Bin Vent

Silos and large hoppers require exhaust air filtration for pneumatic loading or dumping of materials. These applications were primarily bag-style units until the evolution of cartridge filter technology. Easier to maintain and smaller packages allow the cartridge unit to have distinct advantages. Donaldson® Torit® manufactures silo or bin vent dust collectors specifically designed for collecting and cleaning dust from silos, bins, bag dump stations, conveyor transfer points, etc. Because applications vary widely, optional features are numerous. They can be fan-powered or unpowered, filters can be reconditioned or cleaned with compressed air pulse cleaning or a mechanical shaker, and filters can be cartridges, filter packs, pleated filter bags, envelope bags, or socks. Important considerations for equipment selection include filtration efficiency, maintenance requirements, and the time required to replace filter media. Before selecting a dust control system, dust characteristics including explosion hazards must be evaluated.

Silos and large hoppers require exhaust air filtration for pneumatic loading or dumping of materials. These applications were primarily bag-style units until the evolution of cartridge filter technology. Easier to maintain and smaller packages allow the cartridge unit to have distinct advantages. Donaldson® Torit® manufactures silo or bin vent dust collectors specifically designed for collecting and cleaning dust from silos, bins, bag dump stations, conveyor transfer points, etc. Because applications vary widely, optional features are numerous. They can be fan-powered or unpowered, filters can be reconditioned or cleaned with compressed air pulse cleaning or a mechanical shaker, and filters can be cartridges, filter packs, pleated filter bags, envelope bags, or socks. Important considerations for equipment selection include filtration efficiency, maintenance requirements, and the time required to replace filter media. Before selecting a dust control system, dust characteristics including explosion hazards must be evaluated.

Downdraft Tables and Benches

Dust collection can be achieved at individual workplaces or stations using downdraft tables and benches having integrated fans and filtration systems. These tables can also be connected to a much larger dust collection system where a central dust collector is stationed remotely. Downdraft tables and benches accommodate a wide variety of industrial jobs that generate particulate including sanding, gluing, deburring, grinding, welding, and more. Features include:

Dust collection can be achieved at individual workplaces or stations using downdraft tables and benches having integrated fans and filtration systems. These tables can also be connected to a much larger dust collection system where a central dust collector is stationed remotely. Downdraft tables and benches accommodate a wide variety of industrial jobs that generate particulate including sanding, gluing, deburring, grinding, welding, and more. Features include:

- Provide symmetrical airflow across the total work surface

- Built-to-order benches mandate an operator-clean breathing zone

- Vented backs, adjustable side panels

- Self-contained, requiring no ductwork

This portable downdraft table is used to protect the operator from airborne dust while grinding and sanding composite helicopter parts. Here the downdraft table is undergoing airflow testing prior to shipment to the customer.

Read more about Downdraft Tables and Benches here.

Wet Dust Collectors

When handling metals known to be explosive, SysTech supplies wet dust collectors that effectively and safely capture combustible metals such as magnesium, titanium, and aluminum. They are available as part of a downdraft table or a walk-in filtration room and as a self-contained scrubber that can be used for ambient collection or ducted to any existing tables or hoods.

The units for combustible dust collection are compliant with NFPA and OSHA standards.

Ultra High-Efficiency (UHF®) System

Particulate collector applications and collection systems that handle “sticky” dust in saturated airstreams are difficult to address with either a dry or wet collector. Handling those dusts that are not dry nor wet, spawned the Ultra High-Efficiency (UHF®) System was specifically designed for those applications. The UHF filters out smoke and sticky oily emissions using a rolling bed of designed filtration media, capturing particulate down to sub-micron in size at a low-pressure drop and horsepower requirement. Finding solutions to these applications mandates that the UHF option be evaluated before proceeding with your equipment selection.

Particulate collector applications and collection systems that handle “sticky” dust in saturated airstreams are difficult to address with either a dry or wet collector. Handling those dusts that are not dry nor wet, spawned the Ultra High-Efficiency (UHF®) System was specifically designed for those applications. The UHF filters out smoke and sticky oily emissions using a rolling bed of designed filtration media, capturing particulate down to sub-micron in size at a low-pressure drop and horsepower requirement. Finding solutions to these applications mandates that the UHF option be evaluated before proceeding with your equipment selection.

Air Filter Housings

SysTech supplied side access filter housings are fitted with disposable filters, frequently in series, with pre-filters to industrial HEPA and ULPA filters. These air filter housings are available for any application with the following options:

SysTech supplied side access filter housings are fitted with disposable filters, frequently in series, with pre-filters to industrial HEPA and ULPA filters. These air filter housings are available for any application with the following options:

- Materials of construction (Aluminum, galvanized, and stainless steel)

- Indoor or outdoor location

- Filter efficiency

- Temperature of airstream

- Airflow capacity

- Bag-In Bag-Out (BIBO)

- Monitor pressure gauges

- Factory welded transitions

- Isolation dampers

When applied industrially, these housings typically contain HEPA filters, which are designed to remove 99.97% of airborne particles 0.3 microns in diameter. If additional purity is required, ULPA filters that are 99.999% efficient for the removal of 0.1 micron-sized particulate are used. Both are factory tested to meet necessary regulatory requirements for applications in hospitals, biotechnology, biomedical, laboratories, food processing, pharmaceutical, and semiconductor fabrication. A Bag-In Bag-Out (BIBO) option is available for applications where containment is critical for material disposal.

Industrial Dust Collection Systems Manufacturers

We represent the most trusted manufacturers and offer a full selection of products to meet most industrial air system applications.

American Warming & Ventilating

As a proven engineering and manufacturing company of louvers and dampers, American Warming and Ventilating is a leader in the air control industry. With a focus on customer satisfaction and quality products, American Warming and Ventilating has become the trusted name for industrial air systems control.

Cincinnati Fan

Fans and blowers used integrally to and in conjunction with dust collectors have been an OEM staple of Cincinnati Fan for many years. As a manufacturer specializing in dust collector fans, they have a significant history of successfully applied products.

Donaldson Company – TORIT®

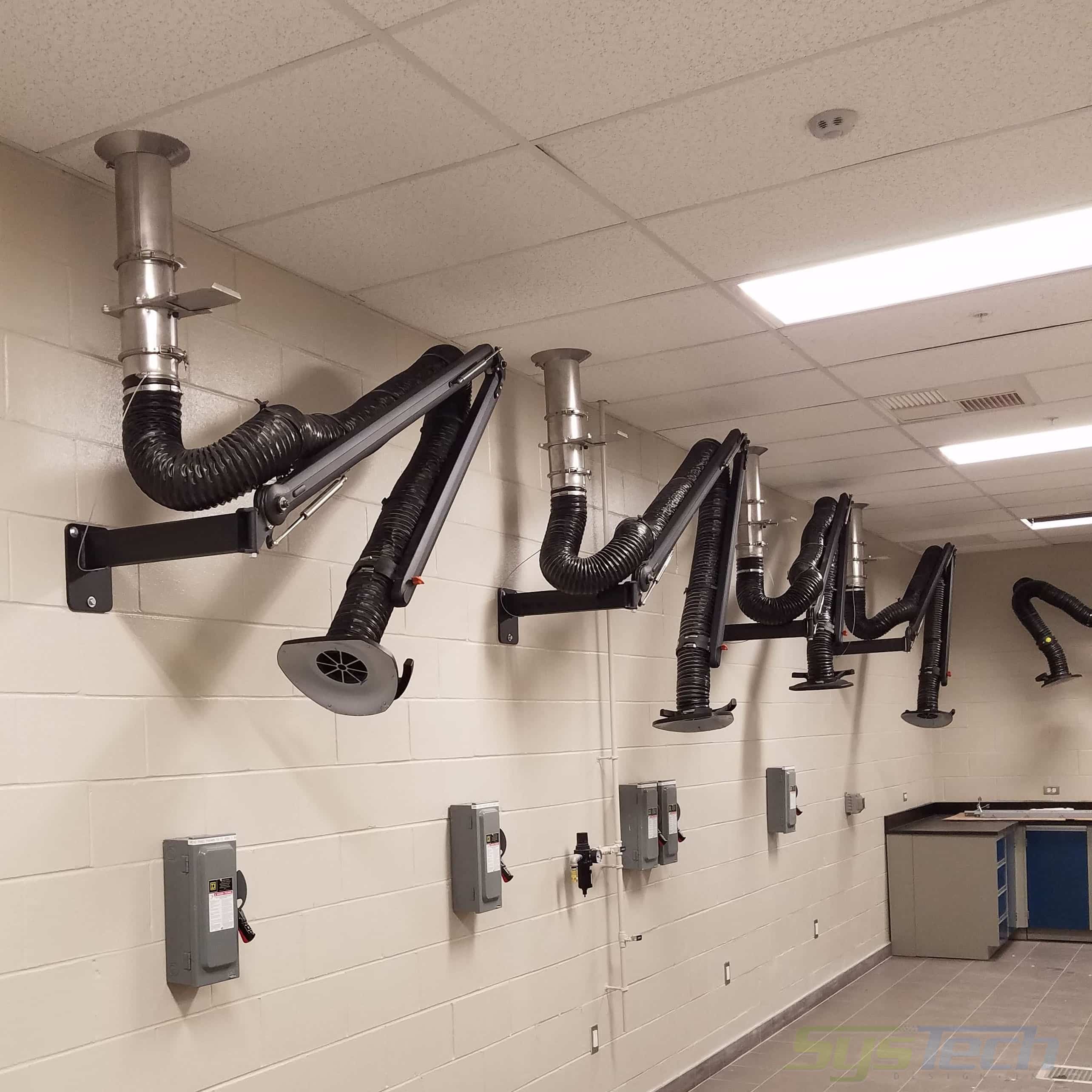

Donaldson Torit is an established name in the dust, mist, and fume collection marketplace. Their innovative designs for both dust and fume collection devices and enhanced filtration media are at the forefront of air pollution control equipment manufacturers. They offer complimentary components for the collection and conveyance of pollution air streams including complete room enclosures, fume exhaust arms, vacuum receivers, and Easy Duct™, a clamp-together duct system that allows changes in duct layout at a significantly reduced installation cost.

DualDraw

DualDraw manufactures downdraft tables and benches in custom design configurations to capture dust at its source. These self-contained dust collectors offer a multitude of advantages for isolated dust and fume collection conditions

VAW Systems Ltd

VAW is a manufacturer of industrial fan silencers and complete facility noise attenuation systems. Comprehensive noise attenuation plans that address protection for personnel and comply with property line noise regulations. Additionally, they offer a broad line of flexible connectors with optional flex materials for airstream conditions, noise attenuation, and abrasion control.

If you need a single piece of equipment or a complete dust collection system, SysTech is readily available to help you develop an air quality control plan you can live with. We offer the most technologically advanced systems and solutions from the leading manufacturers of filtration technology. Are you considering replacing your industrial dust collector or updating your duct system? Consider SysTech’s solutions for low-maintenance and long-equipment-life.

Some Service Areas

Pittsburgh, PA | Butler County, PA | Allegheny County, PA | Westmoreland County, PA | Scranton, PA | Lancaster County, PA | Berks County, PA | Bucks County, PA | Wilkes-Barre, PA | Baltimore, MD | Montgomery County, PA | Kent County, DE | New Castle County, DE | Reading, PA | Williamsport, PA | Lock Haven, PA | Altoona, PA | Erie, PA | Allentown, PA | Montgomery County, MD | Talbot County, MD | Washington County, MD | Baltimore County, MD | Fredericksburg, VA | Wilmington, DE | Blair County, PA | York County, PA | Elkton, MD | Essex County, NJ | Gloucester County, NJ | Morris County, NJ | Middlesex County, NJ