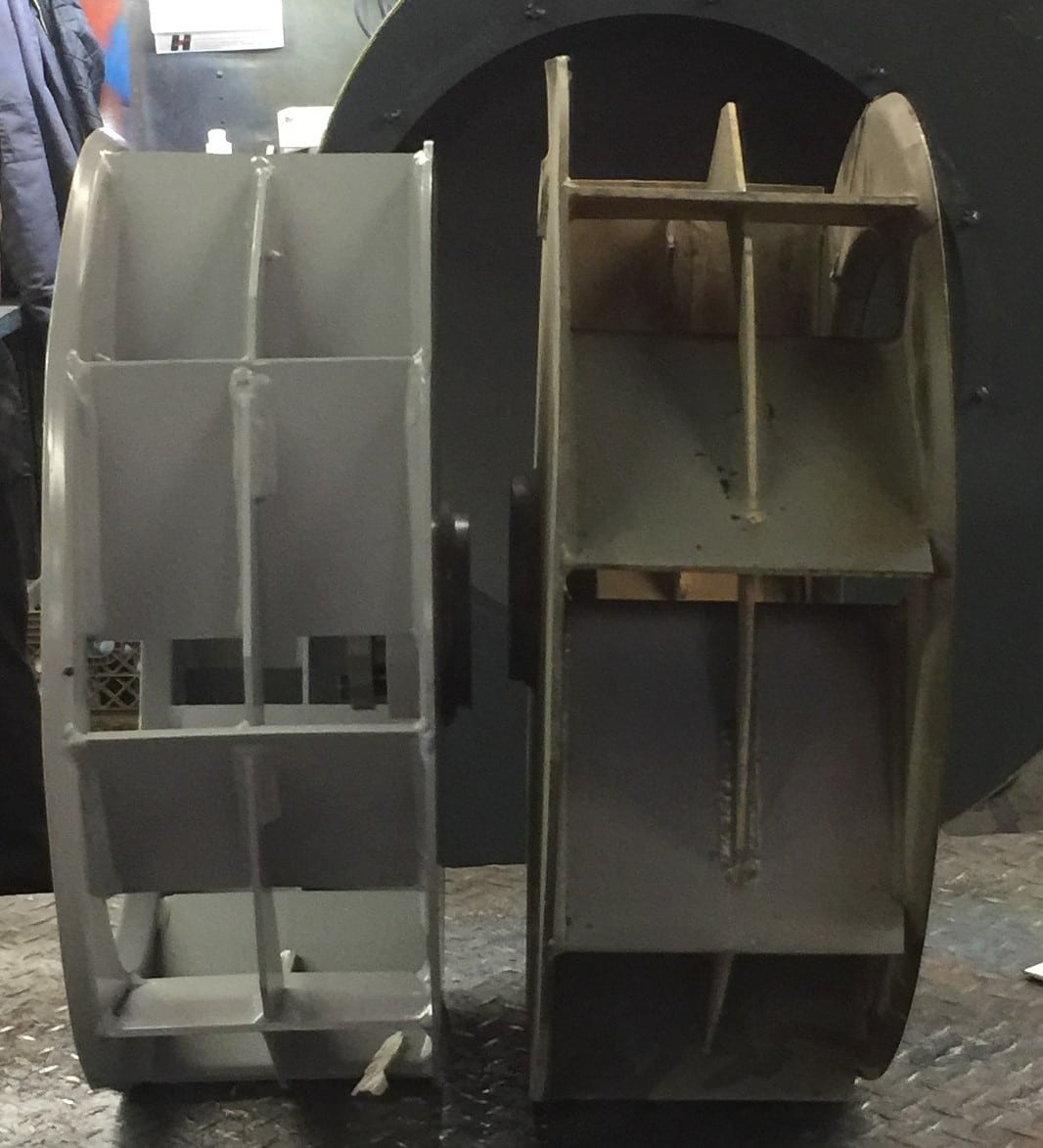

Fan Wheel Replacement

Is your industrial fan in need of a wheel repair, a copy of the original wheel, or maybe a complete replacement? Would expedited shipment of a replacement keep your production “up to speed”?

- If you need a fan or wheel replaced in less than a week, call us!

- Replacement fan wheels for all manufacturers are available for standard and expedited delivery.

- If your fan has frequent failures and the wheel is going out of balance or showing significant wear on the blades or liners, we can align the blades and provide wear plates to increase your fan’s performance and life.

- Wheel sizes up to an 84-inch diameter.

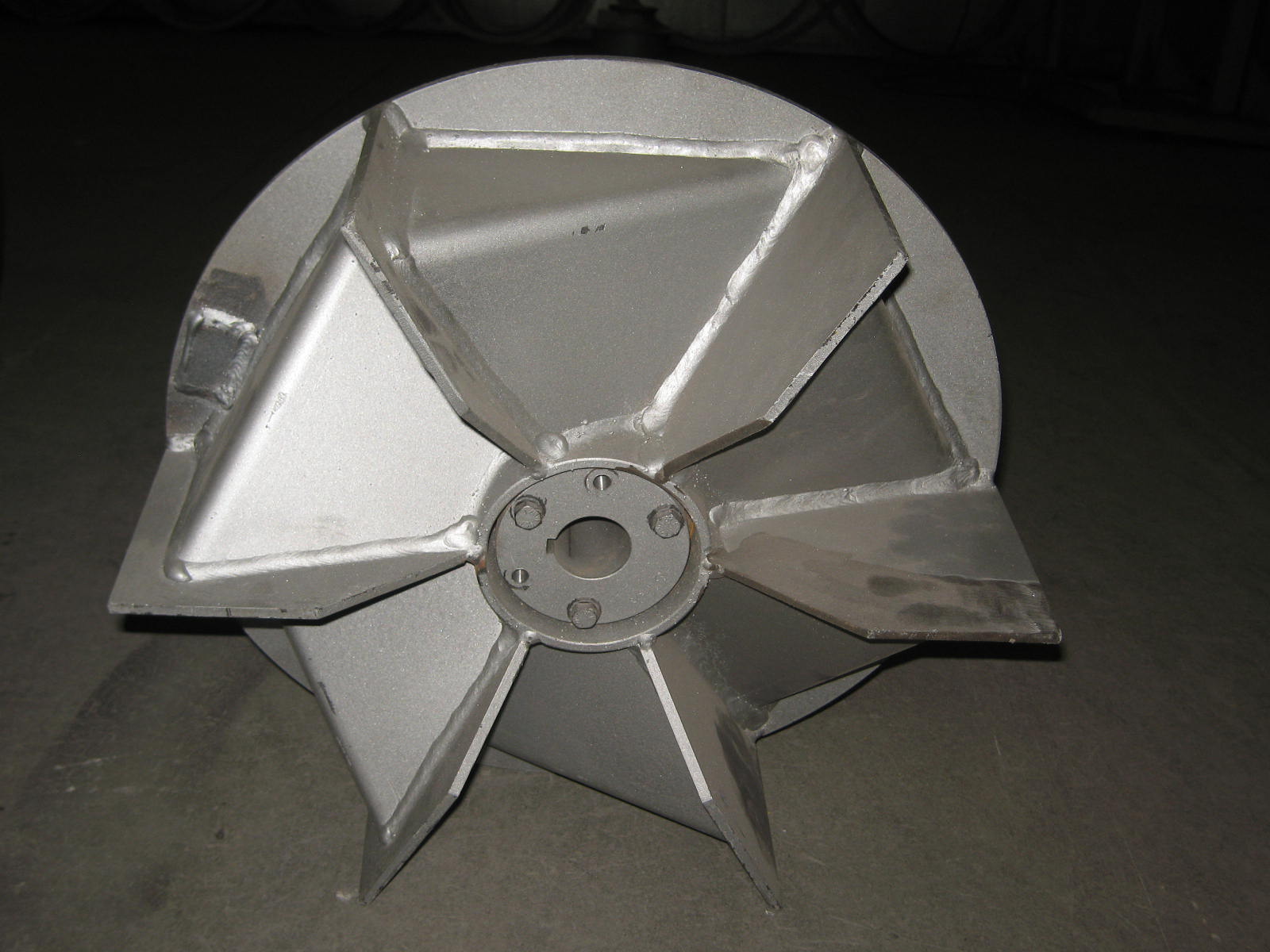

Examples of Replacement Fan Wheel Designs

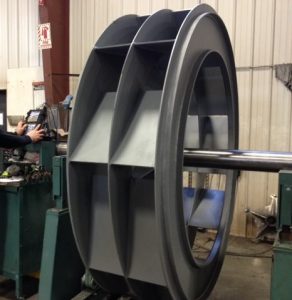

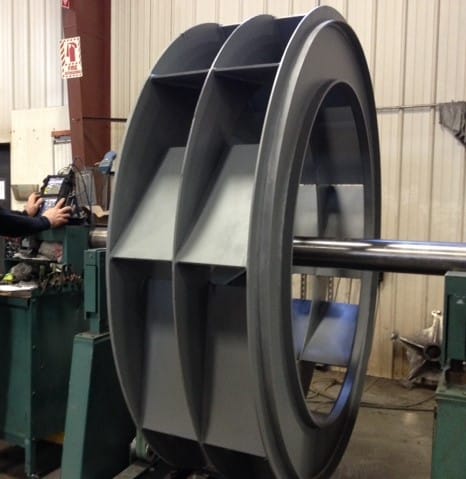

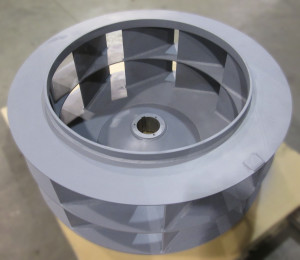

Fan wheels of any configuration and types can be provided as a repair, copy or structurally reinforced, that can be inserted into your fan or blower housing. Some examples of wheel types we’ve shipped are as follows:

Airfoil Fan Wheel – These are highly efficient, clean air fan wheels with blades that are configured like an aircraft wing. Typically applied in general ventilation projects, process heating, and integral to industrial air handlers.

Backwardly Curved Fan Wheel – Blades angle backward with a slight curve. Designed to handle clean air at high volumes and medium static pressures. They can be found in many industrial applications including pollution control systems, cooling systems, and odor control due to its high-volume air movement capabilities.

Backwardly Inclined Fan Wheel – Blades are straight single thickness with a backward angle. They are the smallest wheel diameter for a given CFM. Easily coated or made of special alloys. Applicable to projects such as dust collection systems, pollution control equipment, and furnace exhaust.

Radial Tip Fan Wheel – Blades are slightly curved and angled forward. The wheel is self-cleaning with abrasion resistance which allows them to be used in heavy-duty applications such as forced draft, incineration, and aggressive airstreams.

Radial Fan Wheel – This wheel has flat blades that radiate from the wheel hub. Design is medium air volumes at medium to high static pressure. Typically used in material handling applications such as pollution control systems, material conveying systems and dryers.

High-Pressure Radial Fan Wheel – High-pressure wheel with straight blades radiating from the hub, designed for low-to-medium air volumes at high static pressures. These often applied to chemical processing systems, pneumatic conveying, and combustion air.

Paddle Wheel Fan Wheel – Straight, heavily reinforced blades without front or backplates. Will handle moderate air volumes at high static pressures. Used for material handling and pneumatic conveying applications that require a heavy-duty industrial design.

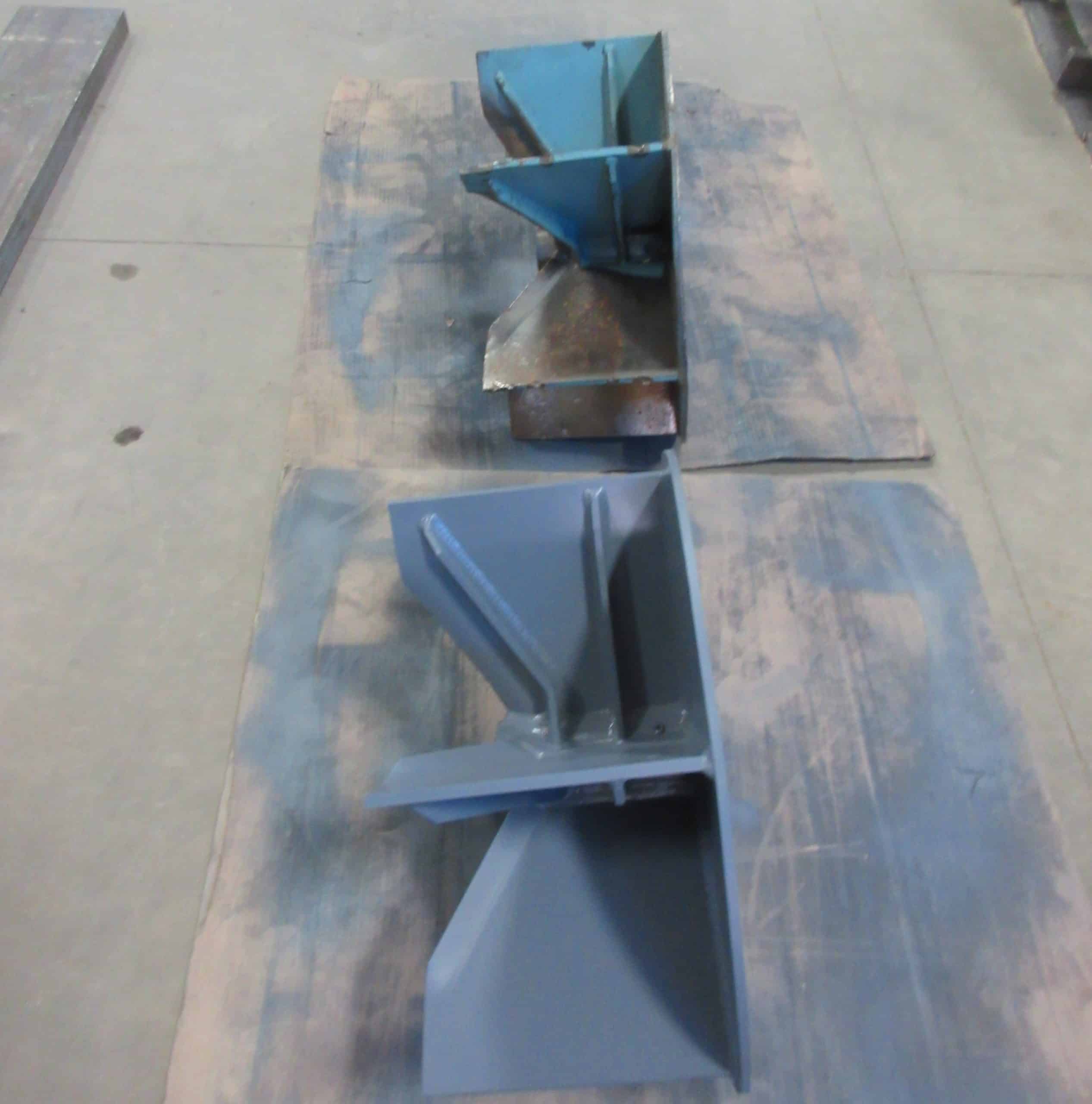

Fan Wheel Options for Erosive Airstreams

When corrosive materials are in an airstream and fans are internally “blasted” by the particulate they will need to be repaired. When they down for service there are modifications that may be instituted to extend the life of the fan.

- Nose Liner – Used on airfoil fan wheels, the nose liner will be secured around the widest part of the blade. It will be adding carbon or stainless steel to the existing blade, therefore making the blade thicker.

- Backplate Liner – The backplate liner is a thicker piece of carbon or stainless steel that is secured to the back of each blade. The back of the blade comes directly into contact with the erosive airstream, which causes it to require the most reinforcement and therefore a thicker piece of steel.

- Blade Liner – The blade liner is a thinner piece of carbon or stainless steel that is placed on the front of the blade. The front of the blade is less susceptible to erosion because it is not coming into direct contact with the airstream. This causes the front of the blade to not require as much reinforcement compared to the back of the blade.

When you’re ready to act on a replacement wheel, call us and submit our Replacement Wheel Questionnaire.