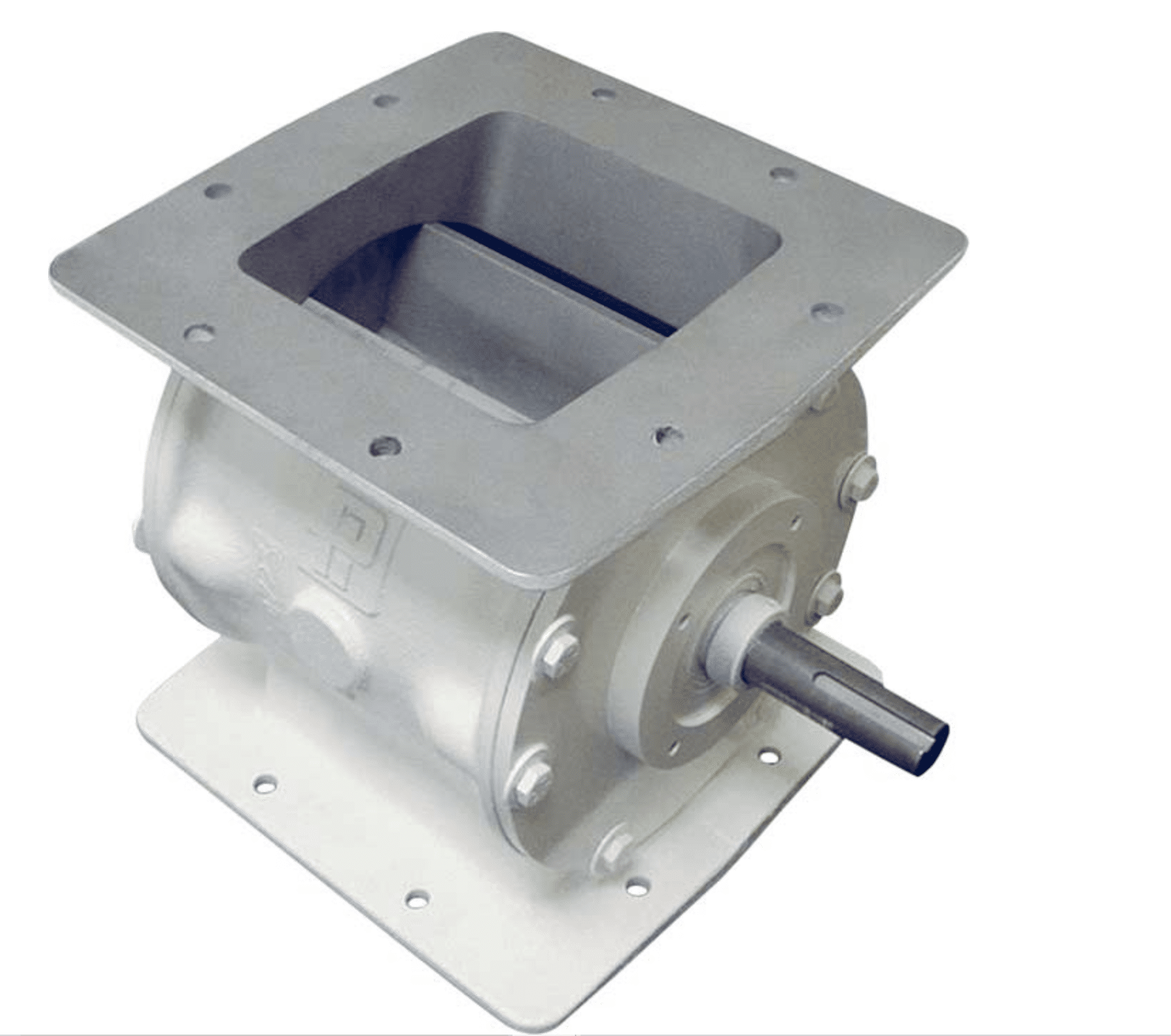

Description

Rotary valves are tested and certified to comply with NFPA-69. Completed testing at a “knowledgeable test authority” certifies the valve complies with NFPA-69 rotary valve design criteria. Testing showed the valve to exceed the required testing pressure of 1 barg and withstood deflagration pressures up to 2.3 barg. Besides compliance with NFPA 69, the valves are also an economical and cost-effective tool for creating an airlock between dust collectors and the collection containers. P Lastly, a direct drive motor eliminates the hassle and maintenance of dealing with belts.

Included Features:

- Sizes: 6, 8, 10, and 12″ square

- Up to 300 Fahrenheit operating temperature

- Up to +/- 3PSI pressure differential

- Cast iron construction

- Direct drive gear motor (29 RPM)

Options:

- Explosion-proof motors: For use in hazardous environments.

- Beveled Rotor Tips: Increases operating efficiency. Used with find dust that can pack between housing and blades.

- Motion Switch: Monitors loss of speed or zero speed.

- Flexible Rotor Tips: Used in applications with stringy or fibrous products.

Reviews

There are no reviews yet.