Description

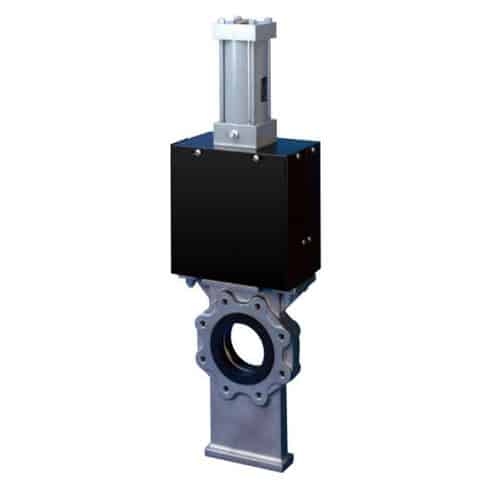

The High-Speed Isolation Valve provides a solution for vital explosion isolation applications. It operates in milliseconds to provide a mechanical barrier within a pipeline. The High-Speed Isolation Valve has a stainless-steel body incorporating a full ported stainless-steel valve gate. The valve is designed to withstand a 150 Psi pressure wave from a deflagration without deformation. Closure is achieved in milliseconds by rapidly discharging nitrogen into a piston actuator. The nitrogen is supplied by an IEP Technologies High-Rate Discharge Bottle. Detection is typically provided by an IEP Technologies explosion pressure detector. The detector is monitored by an IEP Technologies control unit which provides supervision, alarm, system actuation and process shutdown. Typical applications for the valve include explosion isolation on dust collectors, mills, fans, vapor recovery lines, dryers, and other interconnected process equipment.

Advantages:

- Provides mechanical barrier within milliseconds after detection of an explosion.

- Full-bore construction minimizes pressure drop and prevents product build-up.

- ANSI B16.5 150# or DIN 2501 PN10 mounting flange options.

- Sound construction and unique design minimizes maintenance.

- Valve seat and liner materials available for any application.

- Minimal reconditioning required following actuation.

- No gate deformation when subject to explosion pressures up to 150 psig.

Reviews

There are no reviews yet.