Ventilation for Large Industrial Facilities

Ventilation requirements of industrial buildings are driven by the manufacturing processes and activities taking place within the facility. Ventilation for ambient temperature control may be dictated by the number of occupants, the process, or the stored materials. The facility may require supplemental cooling, heating, or air cleaning. Equally important to air movement is noise attenuation issues and addressing hazardous fumes or potential combustible dust situations. When evaluating all these parameters and potential solutions, we need to be aware of the building layout and construction – block, brick, metal, or wood structures.

Whatever the process, whether a furnace, an extruder, mixer/blender, a compressor, large motors, a packaging operation, or a maintenance shop, they all impact the way a building is to be ventilated.

“There is not a cover-all template for proper ventilation of a large industrial space. It is critical to understand the customer’s process, existing ventilation components, as well as their expectations. Most plants require some form of spot ventilation, as well as general air movement equipment. It is the synergy of those individual ventilation components that must be considered to ensure a proper ventilation system that performs to maximum efficiency and longevity.” – Zach Fausnaught 2014

Large Building Ventilation Applications

Applications for large space ventilation are numerous:

- Rolling mills

- Poultry Houses

- Fruit and Produce Storage Facilities

- Foundries

- Shale Gas Compressor Stations

- Warehouses

- Motor Room Ventilation

Considerations when designing Large Ventilation Systems

Design considerations include:

- Air changes per hour (ACH)

- Amount of dust, fume, and mist being generated

- Location of processes that generate dust, fume, and mist

- BTUH equipment heat rejection

- Solar loads

- State and/or local ordinances

- Environmental considerations

- Permissible Noise Levels (PNL)

- Equipment layout within a facility

- Stratification of air temperatures with the facility

- Site location

- Local weather

- Potential of hazardous gases

- Available power

Components for Building Ventilation Projects

Components for the ventilation system:

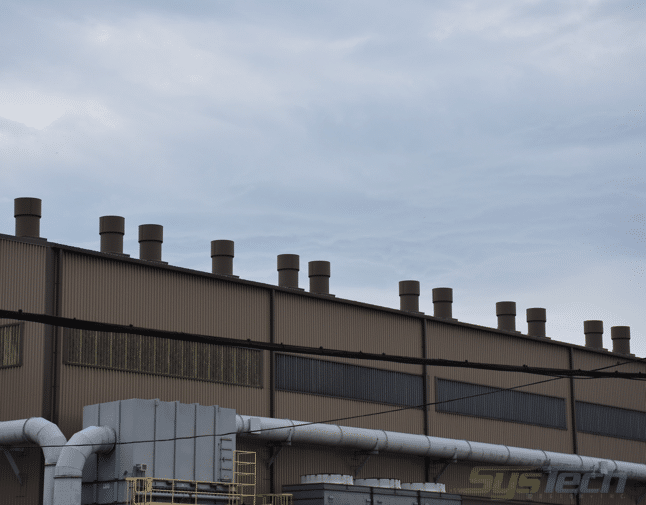

- Supply and Exhaust Fans – in wall or roof configurations

- Cooling Fan Silencers

- Louvers, Dampers & Diffusers

- Side Access Filter Housings

- Ridge Vents

- Intake Hoods -weather and gooseneck designs

- SysTech custom Ventilation Modules

- Electric Unit Heaters

- EXP Unit Heaters – catalytic, electric or hot water

- HVAC Units

- EXP Gas detection Purge Systems

- Electrical Control Packages

Buildings may be steel pre-engineered, brick, block, or brick construction, typically with roof exhaust and wall supply openings, with fan-powered ventilation modules moving large volumes of air. SysTech has designed ventilation projects using the principles of air changes per hour, dilution of concentrated contaminants, or source capture of a pollutant. Air change and dilution designs employ passive or natural ventilation or active or mechanical ventilation techniques.

Each ventilation design package is tailored to available utilities, local weather conditions, hazardous and/or explosive nature of the conveyed gases, ambient air quality, occupational safety and comfort, number of personnel on-site, noise criteria and specific requirements required by a client. Our Natural Gas Compressor Station Case Study demonstrates SysTech’s commitment to the customization of our steel building ventilation systems.

Important Criteria When Designing Large Building Ventilation Systems

Important criteria when designing large building ventilation systems:

- Heat – Furnaces, heat treat ovens, plating lines, spray dryers and large compressors produce large volumes of heat that need to be exhausted from the building to run properly.

- Noise – Noise is generated by the ventilating fans, turbine and engine exhausts, the machinery of production, or perhaps construction machinery when the facility is being constructed. We need to address noise mitigation not only at the facility but the impact on the community surrounding the facility. Noise levels at property lines are a significant factor at well site locations. SysTech has addressed mitigating building noise with custom-designed our own SysTech Lo-Noise™ ventilation modules. Click here to learn more about SysTech Lo-Noise™ ventilation modules.

- Odor – The manufacturing process can produce odors that when released are obnoxious to the surrounding community.

- Dust, fume, and mist – Maintaining air quality by capturing process generated pollutants.

- Gases and Vapors – These could be an asphyxiant gas or explosive gas, requiring consideration of equipment construction and explosion protection.

- Spot heating or cooling of office space within the larger enclosure.

- Other factors determining the final design include the geographic location of the facility, equipment installed, heat loads, and on-site staffing for potential maintenance issues.

We’ve successfully navigated the challenges posed by a lot of these buildings and look forward to helping you solve your ventilation questions. We have the experience, the necessary components, the installation knowledge, and we’re ready to push the start button.

Optional Facilities Ventilation Walkthrough, Inspection, or Troubleshooting

Let SysTech be part of your Facility Ventilation Solutions

SysTech is experienced in developing industrial noise control solutions for a wide range of industrial environments. Call SysTech to discuss your Ventilation of Large Industrial Facilities needs.