Industrial Air System Components

Industrial air conveying systems are about air movement for ventilation purposes, whether the design has air moving along a duct system or across a building interior space. Air conveying systems can be simple or complex, but in both cases, the primary component is a fan, blower, or vacuum producer.

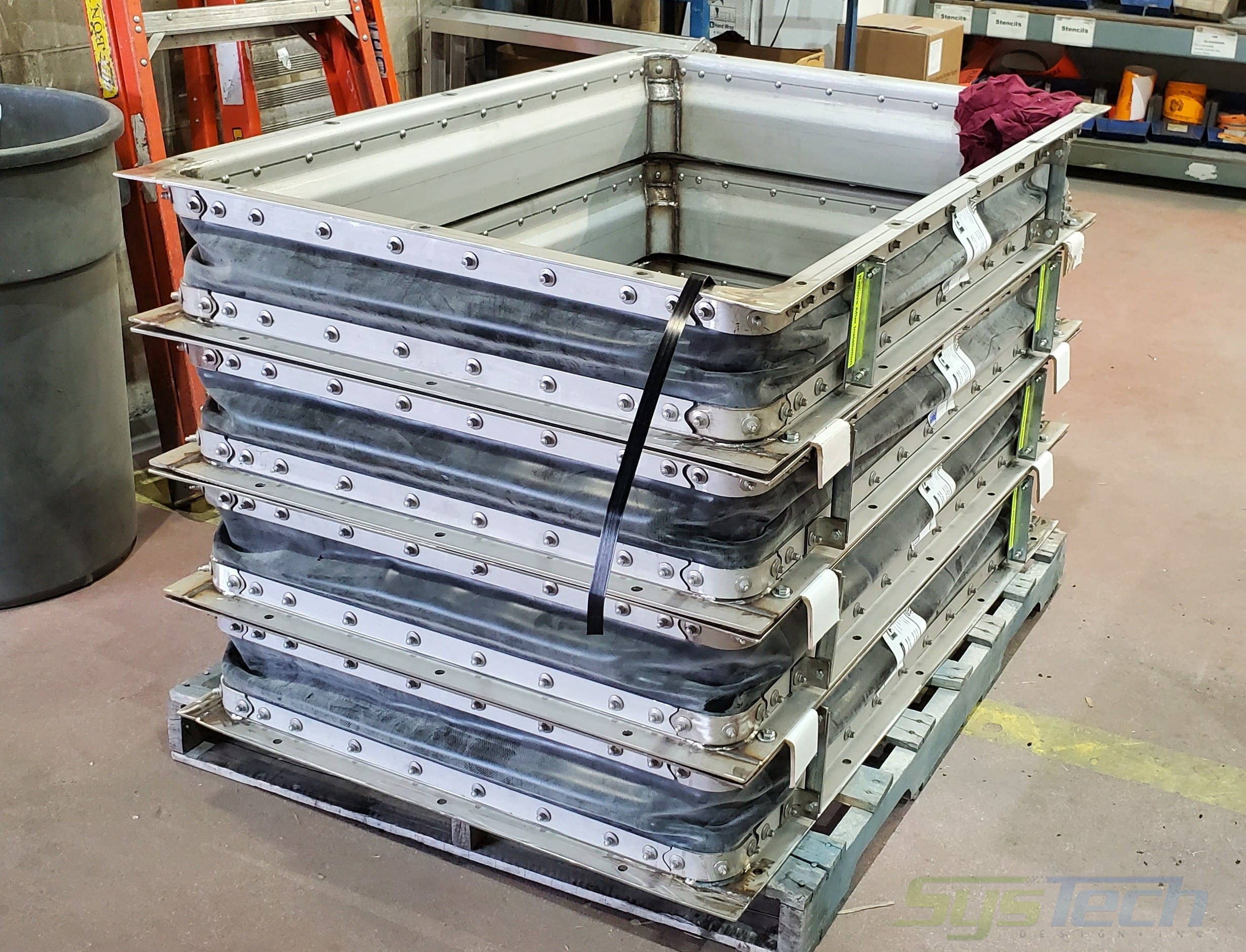

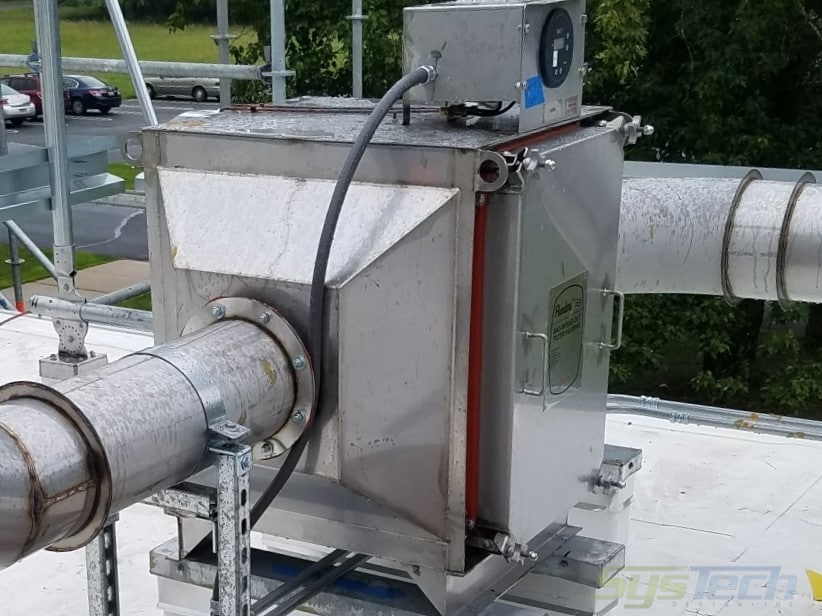

A simple design would be a rooftop or wall exhaust fan with an air intake louver (to prevent weather entrainment) that provides internal heat relief. In contrast, the more complex systems tend to be process-related and consist of duct or vacuum tubing, an air mover either a fan or blower, flexible connectors, a flow control device such as a damper or VFD, pollutant capture hood, air cleaning device, for example, a dust collector or scrubber, discharge stack and silencers for noise control. In both cases, effective air conveying systems are designed around the airstream composition and configured using quality components with the proper materials of construction. And, if the airstream has wide temperature fluctuation or the constituents are bulk materials, corrosive, erosive, or merely clean air, coupling the proper components together creates a long-term solution.