Dust Control Booths

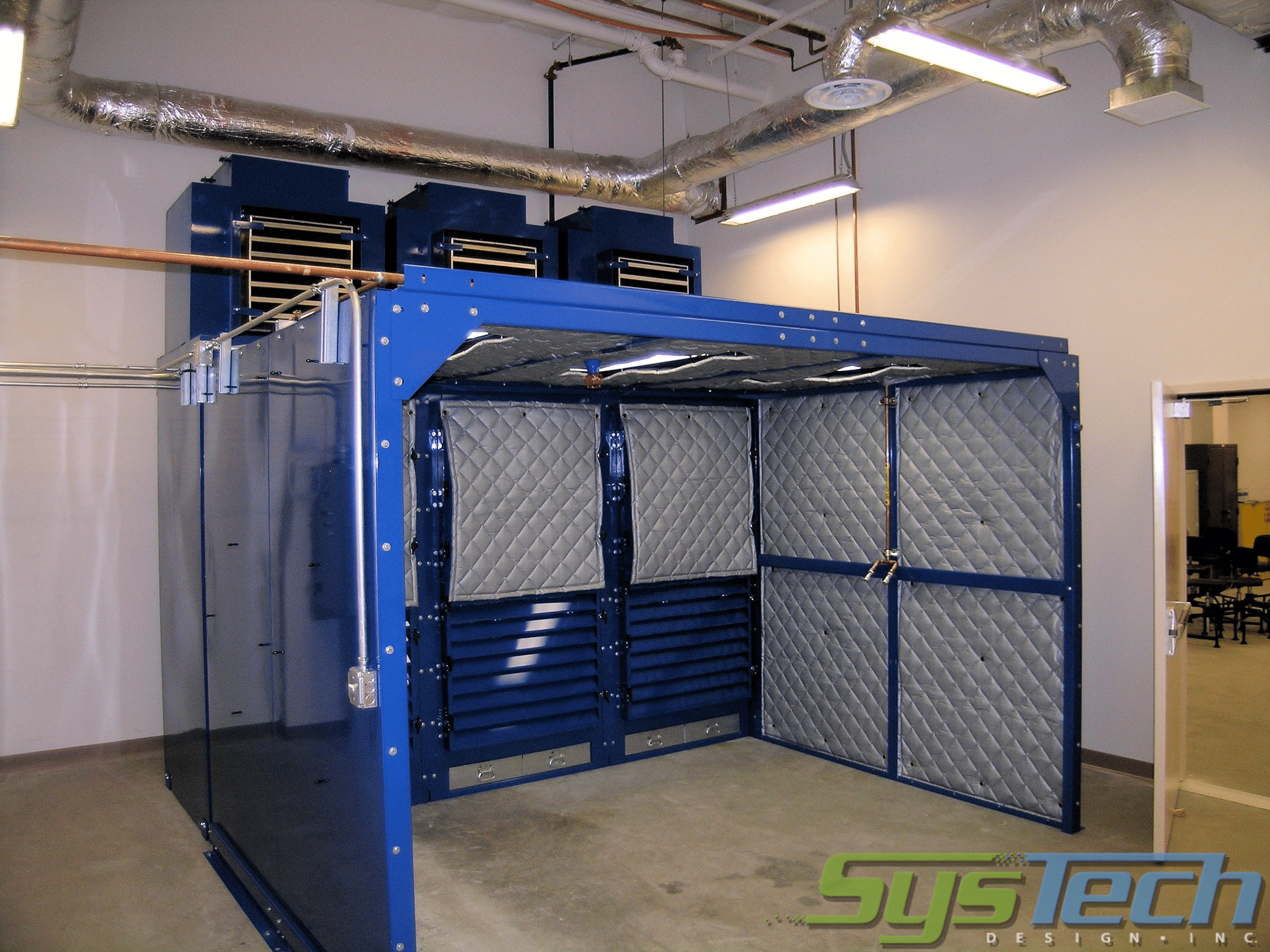

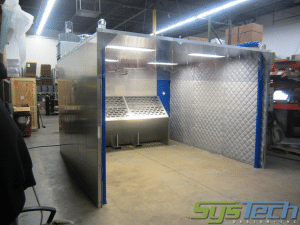

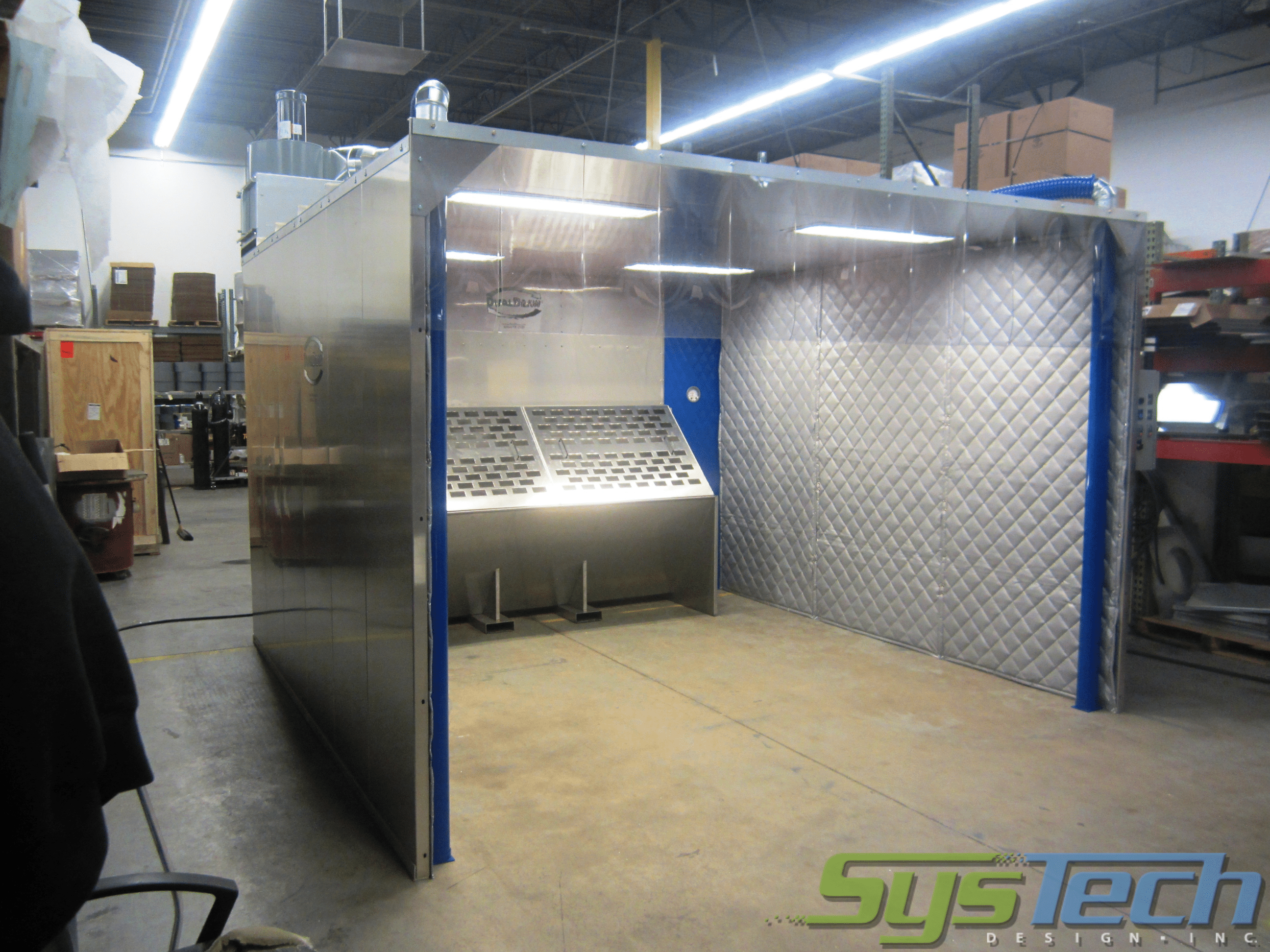

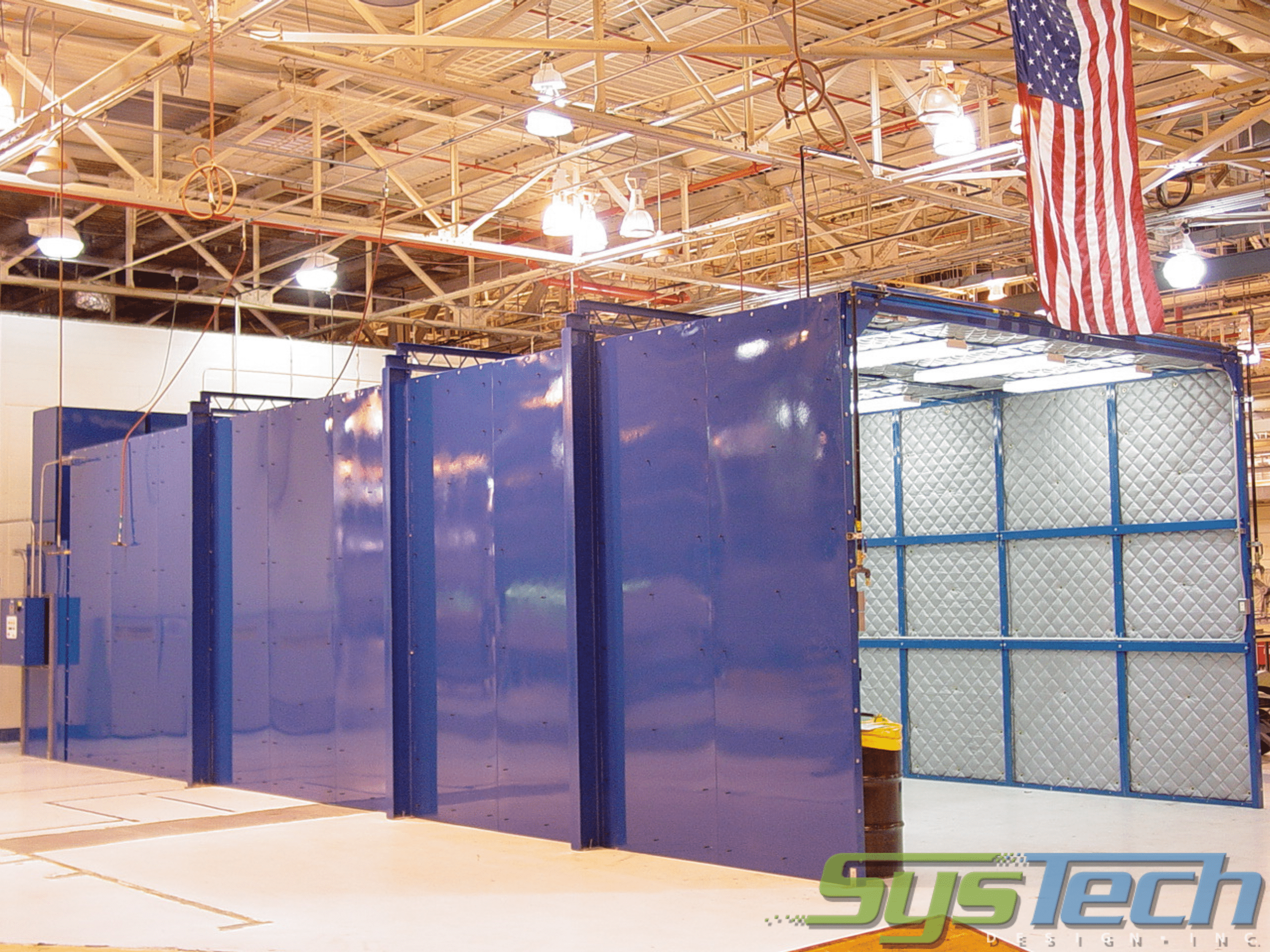

Isolation of small areas or processes within a larger facility is a cost-effective means to control plant air quality. Enclosing a dust source and containing the “dirty air” in a walk-in booth or enclosure, minimizes the amount of air that needs to be cleaned and thus the cost of control. Dust control enclosures encapsulate processes where pollutants are blown around and dispersed within a facility by cross drafts, man coolers, compressed air, or by rotating equipment like sanders and grinders. Enclosures can be rigid wall sheet metal construction or a soft wall design using vinyl curtains or noise blankets.

Advantages of Dust Control Booths

- Moveable

- Free of cross drafts

- Lowest dollar per CFM of all dust collection process options.

- Isolate dusty areas within a plant

- Captures and contains all the dust from the operation

- Cost-effective verses a ducted dust collection system

- Windows allows view of the operator in case of emergency

- Employee safety as noise is attenuated using noise blankets

Applications for Dust Control Booths

- Work stations

- Walk-in Clean Air Stations

- Self-Contained Filtration Booth

- Dust Control Booth

- Dust Containment Booth

- Weigh stations

- Weld stations

- Grinding booths

- Assembly areas

- Blackout Inspection booths

- Noise control enclosures

- Equipment dedusting

- Bag filling operations

- Aircraft wings

Typical Options for Dust Control Booths

- Filtration of captured particulate by way of a continuous duty pulse cleaning dust collection or a bank of replaceable throwaway filters

- Noise blankets to attenuate the noise of grinders or other rotating machinery

- Retractable enclosures – The complete booth can be retracted like an accordion

- Retractable roof section for crane access

- Removable panel sections with Velcro attachment to allow movement of materials thru the enclosure

- Custom designs to fit tight space envelopes

We’re ready to show you how encapsulating your dust source will keep your facility clean.