Industrial Fan Silencers

A wide variety of axial and centrifugal fans and single and multi-stage blowers are used in today’s industrial facilities in a multitude of applications. Rotating mechanical equipment such as fans is a common noise source in manufacturing plants. They may be stand-alone or included as components in OEM equipment such as dust collectors and air handling units.

Fans, that are AMCA certified, will indicate “key” noise points on submittal data sheets and will include an inlet, outlet, and housing power and pressure noise levels. Using this information, excessive noise levels are routinely and effectively attenuated with inlet and outlet silencers, housing blankets or wraps, and encapsulating enclosures.

The noise generated by fans can quickly become a significant problem, requiring the use of silencers and wraps. SysTech will work with you to address your specific fan/silencer needs and facility requirements including issues such as:

- Space restrictions

- Maintaining airflow by minimizing pressure loss through the silencer

- Meeting environmental noise regulations and industrial health and safety requirements

- Using construction materials specific to the application

- Providing accessories including rain hoods, transitions, support brackets, and flow measuring devices

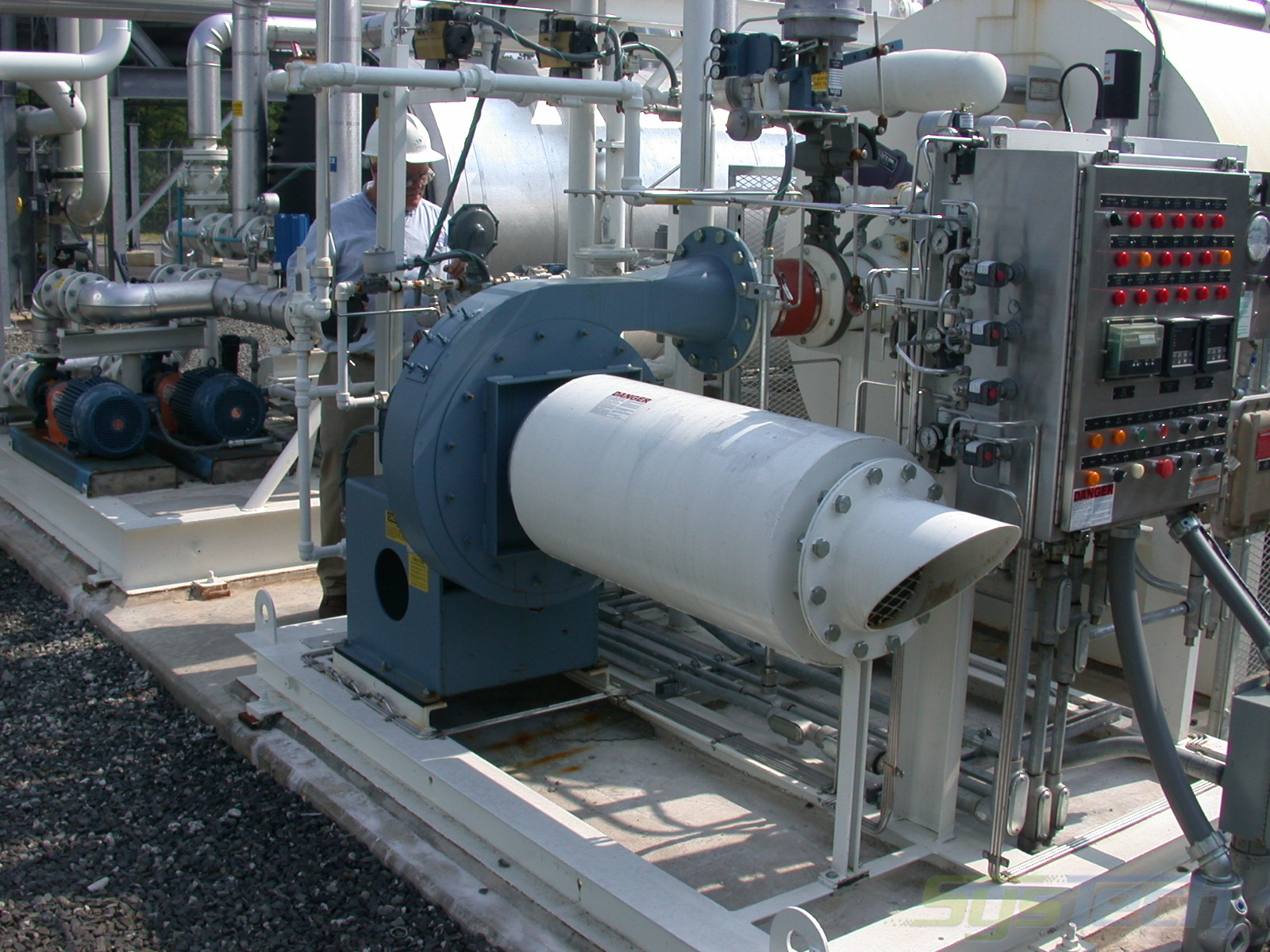

Fan Inlet and Outlet Silencers

Fans, as do most pieces of rotating equipment, produce elevated sound levels. Radiating from the outlet and the inlet of the centrifugal or axial fan noise often requires attenuation. As such, inlet and outlet silencers are frequent additions to fan installations. Frequently they are part of an intake fan system or a discharge fan system, which might include other pieces, including a filter, screen, hood, or a damper. Silencers attached to a round fan flange are called round, tubular, or circular, while those on a rectangular flange are rectangular or box.

Based on their positioning on a fan or blower, inlet and outlet silencers have multiple descriptions including:

- Fan inlet silencer – intake fan system – supply fan silencer

- Fan outlet silencer – discharge fan system – exhaust fan silencer

Each silencer is designed and built for a specific pressure loss and airflow velocity to meet your exact noise attenuation requirement, with industrial silencer casings fabricated from heavy gauge steel. (Exceptions always occur, and there are optional lighter gage designs available for commercial duty applications.)

Options and accessories are many, including rain hoods, a 90-degree flow path (elbow silencer), screens, and renewable packing designs. Special construction materials and paints/coatings are available where high temperatures or corrosive gases are present in the airstream. We can attenuate the required fan inlet and outlet noise but need more information.

SysTech can make a fan silencer selection for your project, but first, we require some particulars. The attached Fan Silencer Questionnaire addresses requisite information that allows us to generate a preliminary selection, or, if we have all the necessary data, a final cost estimate. In some cases, information may not be known, but please provide us with as much detail as possible.

Sound Blankets

When fan or blower housing noise exceeds permitted levels, consider a fan sound blanket wrap or rigid cladding for reducing breakout noise. Noise attenuation, depending upon the fan noise spectrum, is up to 10 dBA @ 3 feet. Blankets are sewn in sections and assembled with Velcro fasteners to totally encompass the fan/blower casing. Typically they are 2 inches thick with a PVC vinyl sound barrier and fiberglass mat insulation. Wrapping the fan housing only, in lieu of enclosing the complete fan assembly, negates the need to ventilate the motor and minimizes floor space requirements.

Noise Control Enclosures

Fans and blowers can be attenuated with double-walled metal casing enclosures, entrapping, and absorbing the unwanted noise. These “metal boxes” built of aluminum, galvanized or painted carbon steel, can be equipped with access doors, pipe and duct openings, and ventilation fans as necessary. They can be located indoors or outdoors and are designed to protect workers, allow easy access to the enclosed equipment for servicing, and have minimal impact on the production process.

Identifying Fan System Noise

SysTech can help you solve fan system noise problems including:

- Pulsing noise

- Low rumble

- High pitched squeal

After identifying the system noise, locate specific noise points including:

- At fan inlet going back through the duct or hood

- At fan outlet going into the surrounding environment

- At drive shaft entry into the fan housing

- Drive motor

- Fan housing

- Bearing noise

- Belt noise

- The vibration of the fan assembly

- Excessive duct vibration

- Excessive base vibration

SysTech offers a variety of fan silencing solutions and noise reduction methods for air moving systems. Contact us to see how we can reduce your ventilation system sound to acceptable levels.

Industrial Fan Silencers

An Integral Part of an Industrial Ventilation System

Industrial ventilation fans and blowers incorporate silencers as a standard option, and their individual design is required for effective noise attenuation. Their integration into a ventilation system is a requirement for both process and ventilation air systems.