Fans and blowers are categorized by their airflow design. The predominant categories for industrial fans and blowers are centrifugal and axial flow. Which category selected for an application depends on pressure or vacuum requirements, space for installation, amount of airflow, and airstream constituents.

Industrial Fan Types

Centrifugal fans direct the air at right angles to the airstream as it enters the inlet of the fan and is suited for handling materials in the airstream. Axial fans move the air along the same axis as the airflow out the outlet of the fan and are applied when moving clean air. We title a third category “Special Purpose Industrial Fans” which includes both centrifugal and axial designs used for special processes or specific industry applications.

How do we know fans? It’s what we do every day and although a lot of applications differ, there are basic engineering designs when coupled with experience, prove successful.

Centrifugal, Axial, or Special Purpose Fan?

Centrifugal and axial fans are further defined by the wheel or the impeller that is selected. Differing wheel geometry changes the performance that can be achieved, the obtainable efficiency, and thus the horsepower requirement. When selecting a wheel, what is in the airstream is critical. Clean airstream wheels are selected on CFM and pressure requirements. Axial fans are most often clean air fans. When material and gases are in the airstream, factors like chemistry, explosivity, material loading, particulate size and density, and abrasive characteristics of the dust are important considerations. This is where centrifugal fans are predominating as there is more flexibility with centrifugal fans.

As mentioned, a third important category includes those fans proven to meet the requirements of specific applications. These are specialized designs that perform reliably in extreme conditions. We call these Special Purpose Fans. Certain applications such as paper trim or high temperature in the airstream necessitate a specific wheel selection, fan construction, or mechanical design.

SysTech has had experience with all categories of fans and blowers including:

- Cast aluminum pressure blowers, axial and vane axial fans, industrial exhausters, roof ventilators, centrifugal fans and marine duty fans for a host of air moving requirements

- Building ventilation systems including wall panel fans and rooftop exhausters

- Engineered fans and blowers applied to abrasive, high temperature, material handling, and paper trim “chopper” applications

- Corrosive environment fans constructed of FRP, PVC, SS, polypropylene, and Kynar materials

- Multistage, positive displacement and regenerative blowers used in vacuum and pneumatic conveying systems design

- OEM fans where cataloged equipment needs to be modified to fit into a client’s product

- Dust collector and mist collector fans

Classification of an Industrial Fan

Our application experience with fans and blowers includes industrial blowers, FRP fans for corrosive environments, and high-pressure blowers for a wide range of applications. Our fan and blower equipment classification is as follows:

Industrial Exhausters – These are typically centrifugal fans, of heavy-duty construction applied to a process exhaust airstream. Fan wheels are designed and selected based on the airstream and the environment surrounding the fan.

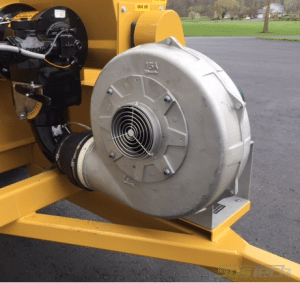

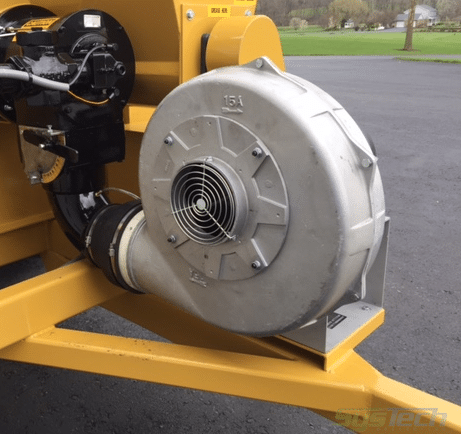

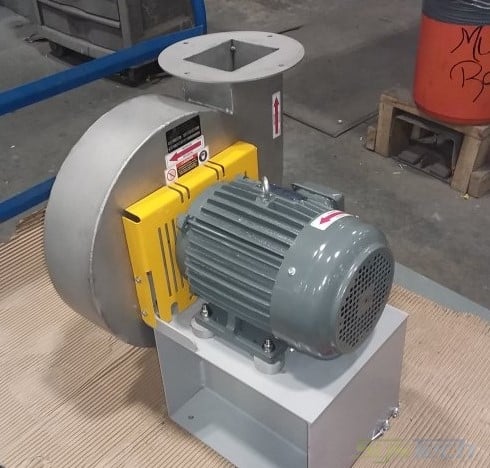

Pressure Blowers – Pressure blowers are characterized by high pressure with low airflow as compared to other centrifugal industrial fans with blower wheel speed a minimal 3600 rpm. They are in single or multi-stage configuration with positive displacement packages for pneumatic conveying systems.

Fiberglass Exhaust Fans – In corrosive environments where factors such as high humidity and aggressive chemicals are present, SysTech will select the materials of construction that perform best in your corrosive environment. Plastic fans in FRP, PVC, and CPVC construction are available options.

High-Temperature Fans – When temperatures exceed 200 degrees fans and blowers are considered high temperatures in direct drive configuration. Where high heat processes up to 2000 degrees F, for ovens and kilns, arrangement changes as does metal, insulation, and auxiliary features. High-temperature fans need concise specifications to be successfully applied.

OEM Fans – Original Equipment Manufacturers require fans and blowers that need to be redesigned to fit into their machinery or process. Standard products just won’t do it. SysTech will assist with the process and suggest solutions to the application.

Industrial Fan Wheel and Propeller Terminology

Fan wheels or propellers determine the model name of a fan, and their acronym would be part of the model number. For example, an HDBI model is a Heavy Duty Backwardly Inclined fan and AF would be an airfoil bladed wheel. Listed below are wheels/propellers we commonly encounter and is not meant to be an all-inclusive list.

Airfoil – Blade cross-section is that of an airplane wing. Highly efficient, clean air design. Typically applied in medium static pressure applications such as general ventilation, process heating, and biomass production. Airfoil fan wheels are compatible with all types of control methods. Both centrifugal and axial fans use the airfoil designed blade.

Backward Curved – Blades are slightly curved and angled backward in the wheel. Designed to handle clean air at high volumes and medium static pressures. Typically used in a variety of industrial applications such as pollution control, cooling systems, and odor control due to its high-volume air movement capabilities.

Backward Inclined – Straight single-thickness blades angled backward. Smallest wheel diameter for given cubic feet of air per minute. Easily coated or made of special alloys. Perfect for projects such as dust collection, pollution control, and oven exhaust.

Radial Tip – Blades are slightly curved and angled forwards. A self-cleaning fan wheel with low wear rates, radial tip fan wheels are designed for higher specific speeds. This allows them to be used in heavy-duty applications such as forced draft, incineration, and abrasive airstreams.

Radial – Flat blades arranged in a radial pattern off the hub. Medium air volumes at medium to high static pressure. These wheels are typically used in a variety of industrial applications such as material handling, pollution control, and dryers.

High-Pressure Radial – Straight blades, engineered for low-to-medium air volumes at high static pressures. These wheels will typically include but are not limited to, chemical processing, pneumatic conveying, and combustion air.

Paddle Wheel – Straight, reinforced blades without shrouds. Designed to handle moderate air volumes at high static pressures. Typically used in material handling, dust collection, and pneumatic conveying applications that require a more rugged design.

Fixed Blade Axial Propeller – Axial Fan wheel, typical cast aluminum airfoil design.

Adjustable Pitch Axial Propeller – Axial impeller that allows each blade to be adjusted to a different angle. This allows a change to the performance of the fan in the field.

Stamped Blade – Fan blades can be stamped on some light duty axial fans for commercial applications.

In-line Centrifugal – Centrifugal wheels are inserted in a tube making the fan an axial design. These are used to gain higher static pressures than a propeller bladed axial.

Industrial Fan Manufacturers

We represent the leading manufacturers of fans and blowers and offer a complete selection of products to meet the needs and requirements of a variety of processes and applications.

AirPro Fan & Blower Company

AirPro is the complete source for industrial fans and dampers. Designed for performance and longevity, AirPro fans are engineered to meet virtually any application requirement. AirPro manufactures a comprehensive standard product line along with high-temperature, paper-trim handling, and API designs. They also specialize in the development of custom fans, built to necessary specifications.

American Coolair Corporation

Coolair has been developing quality building ventilation systems for over 75 years. The comprehensive axial fan product line includes complete building ventilation systems for a diverse range of industries.

Cincinnati Fan and Ventilator Company, Inc.

For over 50 years, Cincinnati Fan has been manufacturing cast aluminum and fabricated steel industrial fans, blowers, and exhausters. In addition to their cataloged products, which include fans ranging from ¼ to 125 horsepower, Cincinnati Fan manufactures custom fan and blower models designed to meet the specific needs and requirements of most applications.

Daniels Fans

A Cincinnati Fan company, Daniels designs and manufactures industrial high-temperature fans in both centrifugal and axial configurations. Options allow airstream temperatures up to 2200°F and include insulated double-wall housings, direct or belt drive, multiple impeller designs, and gas-tight construction.

Envira-North Systems, Ltd

Envira-North is Canada’s largest supplier of industrial/commercial big ceiling (destratification) fans and claims 75 percent of the Canadian market for industrial/commercial destratification and ventilation fans. Their HVLS big fan product and systems enable buildings to perform better; save on heating, cooling, mechanical operating costs and provide a healthier environment for the occupants of the structure.

Hartzell Air Movement

A leader in industrial ventilation, Hartzell produces innovative and efficient air moving products that are known for exceptional quality and reliability. The Hartzell product line includes fans for both general and process ventilation including a complete line of axial fans, centrifugal fans and blowers, an extensive fiberglass product line, and a complete line of make-up air and heating equipment with a full range of options and accessories. Not limited to carbon steel or stainless steel, they offer a complete line of FRP fans, blowers, louvers, and dampers.

Industrial Plastic Fan LLC

IPF manufactures quality PVC blowers and polypropylene blowers for a variety of industrial applications. An ISO 9001-2000 compliant manufacturer, IPF develops fans to precision tolerances, with well-balanced impellers for whisper-quiet operation. IPF plastic fans are well suited for use in corrosive environments, with high degrees of humidity and moisture, as well as exposure to caustics, chlorine, or acids.

Case Studies About Industrial Fans & Blowers

- Bitcoin Mining Center Ventilation

- Compost Facility Aeration Fans

- Maintenance of Roof Exhaust Fans under increased production

- Nitrogen Recirculation System Upgrade

- Solutions Using High Pressure Exhausters in Series

- Ventilation of an Industrial Facility during extreme summer heat

- When Shipping Fans to South America

Industrial Fans & Blower Blogs

- Carbon Fiber Wheels From Hartzell Air Movement

- Chemical Plant FRP Exhaust Roof Fans

- Cincinnati Fan: Your OEM Fan & Blower Supplier

- Fiberglass Fan Construction: A Day at Hartzell Air Movement

- Find SysTech Design in Maryland, DC Metro and Northern Virginia

- FRP Fan Education On The Move

- Hartzell Air Movement Announces Five-Year Warranty

- Hartzell Air Movement Fans and Blowers – Seeing is believing

- Hartzell Fan and Blower Training Programs in Maryland

- Industrial Fan and Air Handling Unit Noise Considerations

- New Cincinnati Fan Motor Offering

- On the Road Again – Hartzell Fiberglass Ventilation Products

- Plant Tour with Hartzell Air Movement

- Road Trip to Cincinnati Fan! Seeing is Believing!

- Small Compressor Room Ventilation

- SysTech Assigned Maryland Territory for Cincinnati Fan Products

- Three Treatment Options for Stainless Steel Fans

- Ventilation of Flammable Vapors

- WWTP Fiberglass Hartzell Fans

Optional Industrial Fan & Blower Walkthrough, Inspection or Troubleshooting

We can help remotely if needed! Industrial Fan & Blower walkthroughs will help us to better understand the magnitude of the Fan & Blower issue and important space constraints that might inhibit a specific mitigation technique.

Let SysTech be part of your Industrial Fan & Blower solution

SysTech is experienced in developing industrial air distribution and movement solutions for a wide range of industrial environments. Call SysTech to discuss your industrial fan & blower needs.

Some Service Areas

Baltimore, MD | Linthicum Heights, MD | Hanover, MD | Columbia, MD | Beltsville, MD | Waldorf, MD | Salisbury, MD | Elkton, MD | Bel air, MD | Hunt Valley, MD | Sparks, MD | Westminster, MD | Hagerstown, MD | Frederick, MD | Germantown, MD | Gaithersburg, MD | Rockville, MD | Potomac, MD | Bethesda, MD | Scranton, PA | Pittsburgh, PA | Lancaster, PA | Downingtown, PA | Erie, PA | Wilkes-Barre, PA | Piscataway, NJ | Morrisville, PA | Reading, PA | Berks County, PA | Bucks County, PA | Bedford, PA | Altoona, PA | Johnstown, PA | Allentown, PA | Carbondale, PA | Lock Haven, PA | Williamsport, PA | Chester County, PA | Dover, DE | Wilmington, DE | Essex County, NJ | Gloucester County, NJ | York County, PA | Middlesex County, NJ | Morris County, NJ | New Castle County, DE | Kent County, DE | Easton, MD | Fredericksburg, VA | Manassas, VA | Winchester, VA | Lancaster County, PA | Lackawanna, PA | Luzerne County, PA | Montgomery County, PA | Ellicott City, MD | Lansdowne, MD | Upper Marlboro, MD