When reviewing fan performance information from a fan selection program, critical fan sound data measured in sound pressure levels (dBA) is often overlooked. And a program input value that can significantly change the resulting dBA levels is the reflectivity or “Q” factor. Recently discussed in “Hartzell Headlines,” Todd Schaefer, Regional Sales Manager at Hartzell Air Movement, discussed different Q factors and how each “Q” factor changed the reported sound pressure levels based on spatial position. Q factors are defined as follows:

Q = 1: Spherical Radiation (IE:Axial fan installed in the middle of stack)

Q = 2: Hemispherical Radiation (IE: Floor mounted Centrifugal fan in a large plant with no reflective surfaces nearby)

Q = 4: 1/4 Spherical Radiation (IE: Floor mounted fan near an interior wall)

Q = 8: 1/8 Spherical Radiation (IE: Floor mounted fan near the inside corner of a room)

Q = 2: Hemispherical Radiation (IE: Floor mounted Centrifugal fan in a large plant with no reflective surfaces nearby)

Q = 4: 1/4 Spherical Radiation (IE: Floor mounted fan near an interior wall)

Q = 8: 1/8 Spherical Radiation (IE: Floor mounted fan near the inside corner of a room)

“Q” Factor influence on Industrial Noise Control

Fan noise control is essential, and using the correct “Q” factor for application analyses is required to meet expected noise attenuation. At SysTech, we consider all elements within a fan system layout to ensure accurate noise levels are met, and the Q factor is an essential one.

An example from the Headlines provides a scenario to show how fan dBA levels change based on the “Q” factor.

EXAMPLE: Hartzell Air Movement Series 41 fan, size 40, with an FA wheel rated at 36,000 CFM and 6.5” WG (.075 lb/ft³) that has a radiated sound pressure level of 84 dBA @ 5 ft. when Q = 2. (Data was generated from Hartzell’s FLOW program.) If the Q value is changed, the difference in the reflectivity factors significantly alters the reported dBA level:

Q = 1: 81 dBA @ 5 ft.

Q = 2: 84 dBA @ 5 ft.

Q = 4: 87 dBA @ 5 ft.

Q = 8: 90 dBA @ 5 ft.

A difference from Q 1 to 8 is nine dBA! In terms of the human ear, that’s a perceived loudness of 2 times.

If we combine this issue with other noise sources in a room or building, it’s easy to see the potential problem created by choosing the correct Q factor.

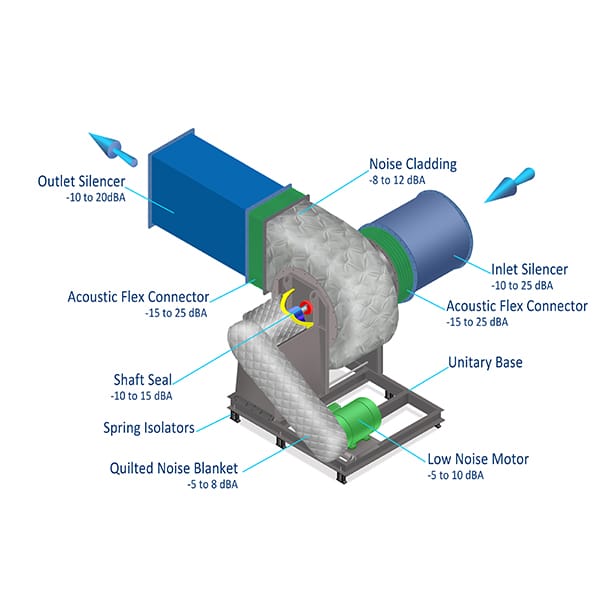

When sound requirements need to be met within a manufacturing facility, be sure to review the reported fan sound levels to ensure your requirements can be fulfilled. If the Q=1 factor is the “standard” on fan sound reports, this output will show the lowest dBA levels, deceiving as each application varies. If in the design phase, adding attenuation to ventilation equipment, knowing the correct dBA levels may impact other important design and equipment selection decisions, from choices of noise control curtains, noise control enclosures for fans, to entire generator room ventilation designs.