Types of Industrial Fans & Blowers

General Ventilation Fans

These fans are often utilized to move uncontained air with in an industrial space and improve the air quality. Designed to handle general ventilation, fume removal, temperature regulation and exhaust applications these fans are capable in multiple disciplinaries. These can include propeller fans, wall ventilation and roof ventilators.

Roof Ventilators

Rooftop-mounted fans are designed as packaged units to be dropped into place on a roof curb. Depending on the design of the ventilation system, they can be configured in exhaust, intake, reversible, or recirculating modes. Fan types include:

- Upblast Exhausters

- Hooded & Recirculating Roof Ventilators

- Upblast & Smoke Ventilators

- Centrifugal Dome Wall & Upblast Roof Ventilators

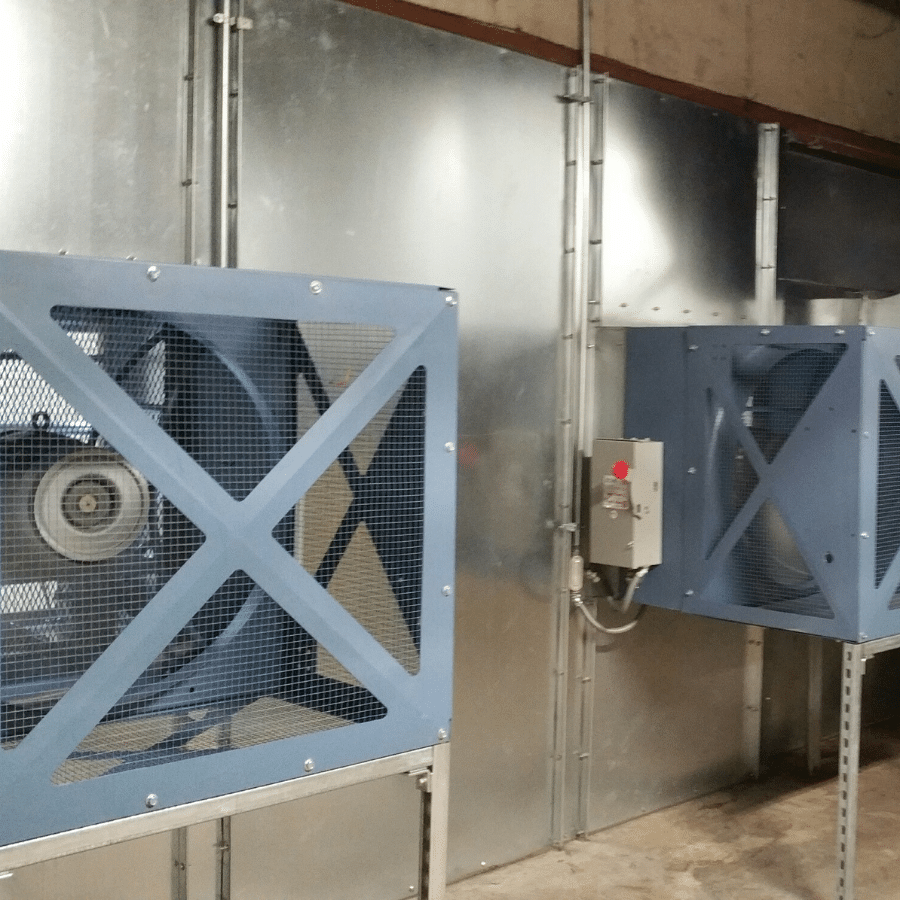

Propeller Fans & Wall Ventilation

Propeller fans, often referred to as ring and panel fans, are designed to adjust the temperature in manufacturing spaces, exhaust smoke and haze from facilities, and provide general air movement for ventilation purposes. They are designed in standard and reverse flow and may be equipped with low-noise rings or attenuators where objectionable noise is an issue.

- Ring & Panel Fans

Process Ventilation Fans

Process ventilation fans are needed when moving, controlling, or containing contaminated or high-temperature airstreams. The air being moved might contain corrosive fumes, airborne particulates, or elevated temperatures. Based on the application, axial or centrifugal fan designs are optional selections.

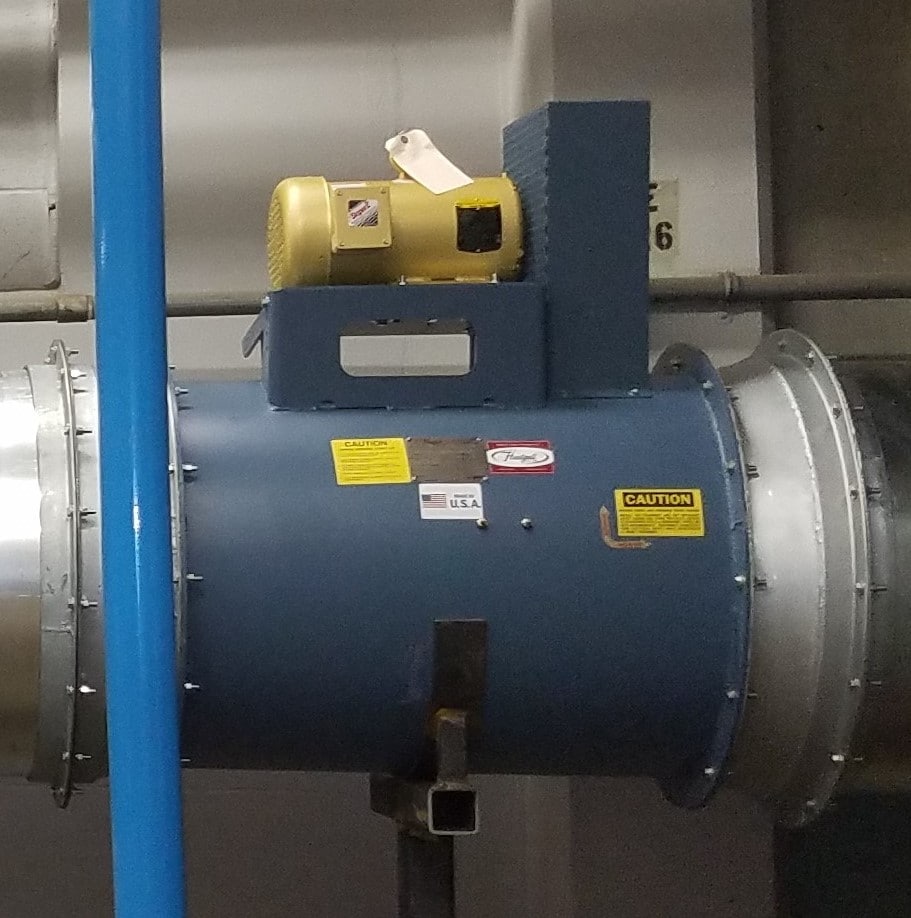

Axial Flow Fans

Axial flow process fans are designed to move small to large volumes of air at low static pressures and temperatures. They have a propeller that creates pressurized air and pushes or draws it in the same direction/axial plane. These fans can cool down areas and processes where ambient outside air is available. They are manufactured in many sizes, direct or belt-driven, and their construction is available in painted carbon steel, stainless steel, aluminum, or fiberglass. Selections include:

- Duct fans

- Duct axial fans

- Vaneaxial fans (fixed pitch)

- Vaneaxial fans (adjustable pitch)

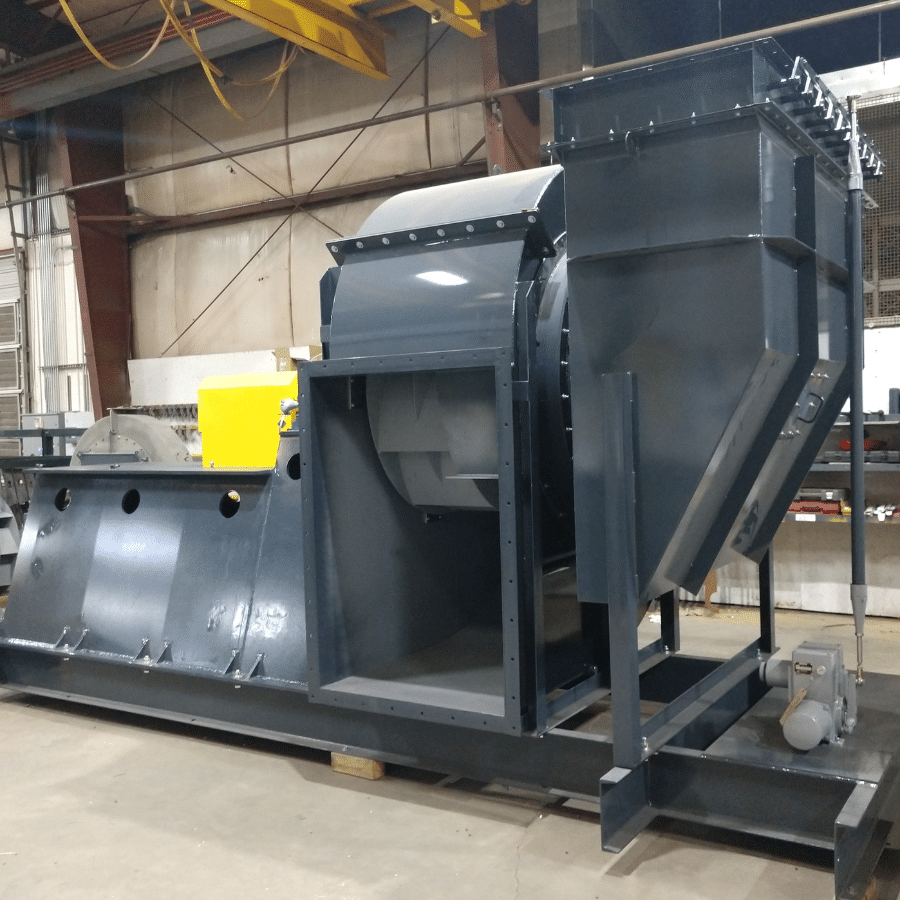

Centrifugal Fans

Centrifugal process fans can operate at higher pressure levels and handle particulate better than axial flow fans, making them a choice for many industrial processes. Unlike axial fans, which have the discharge direction on the same plane, the fan wheels in centrifugal fans are set at a 90-degree difference from the output. These fans are used in material conveying applications and moving “dirty air” in high-temperature airstreams. Examples include:

- Backward curved centrifugal fans

- Square type BC Fans

- Swing-out Centrifugal

- Plug Fans

- Double wide centrifugal Fans

- In-line Centrifugal Fans

- Industrial Exhausters

- Flange mounted Industrial Exhausters

- Turbo Pressure Blowers

- Pressure blowers

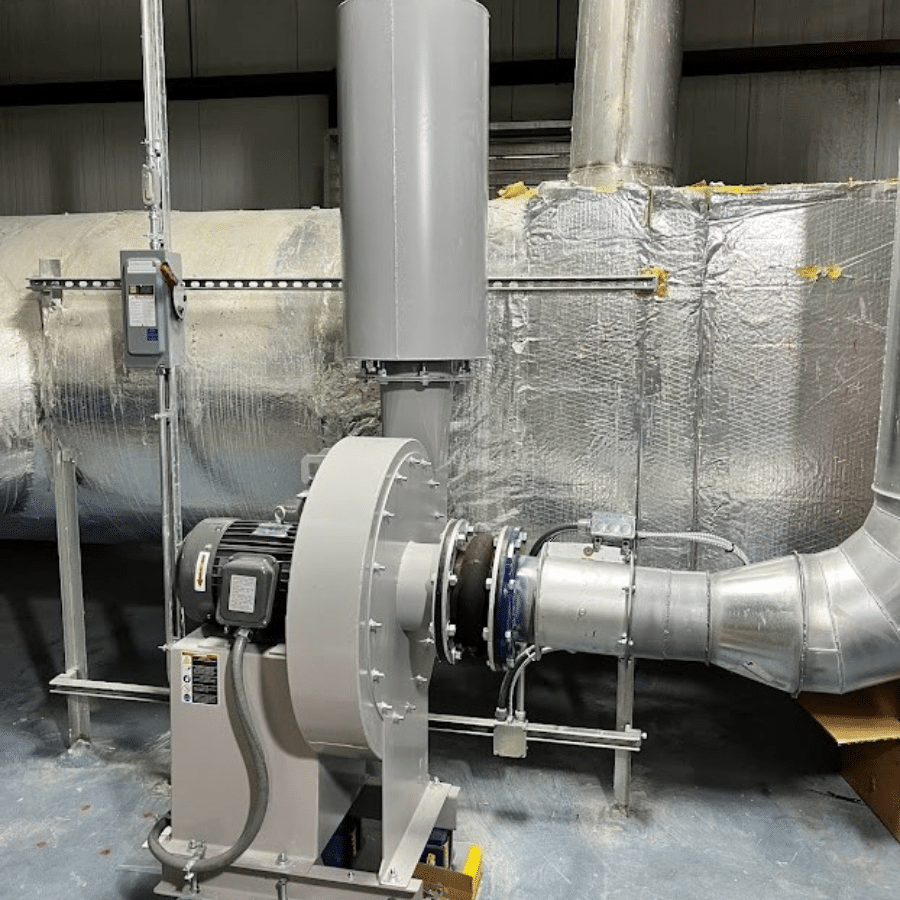

Industrial High-Pressure Blowers

Pressure blowers are a type of centrifugal fan used for higher-pressure applications, such as supplying combustion air or conveying material. Construction is painted steel, stainless steel, or cast aluminum and can be direct or belt-driven depending on performance requirements.

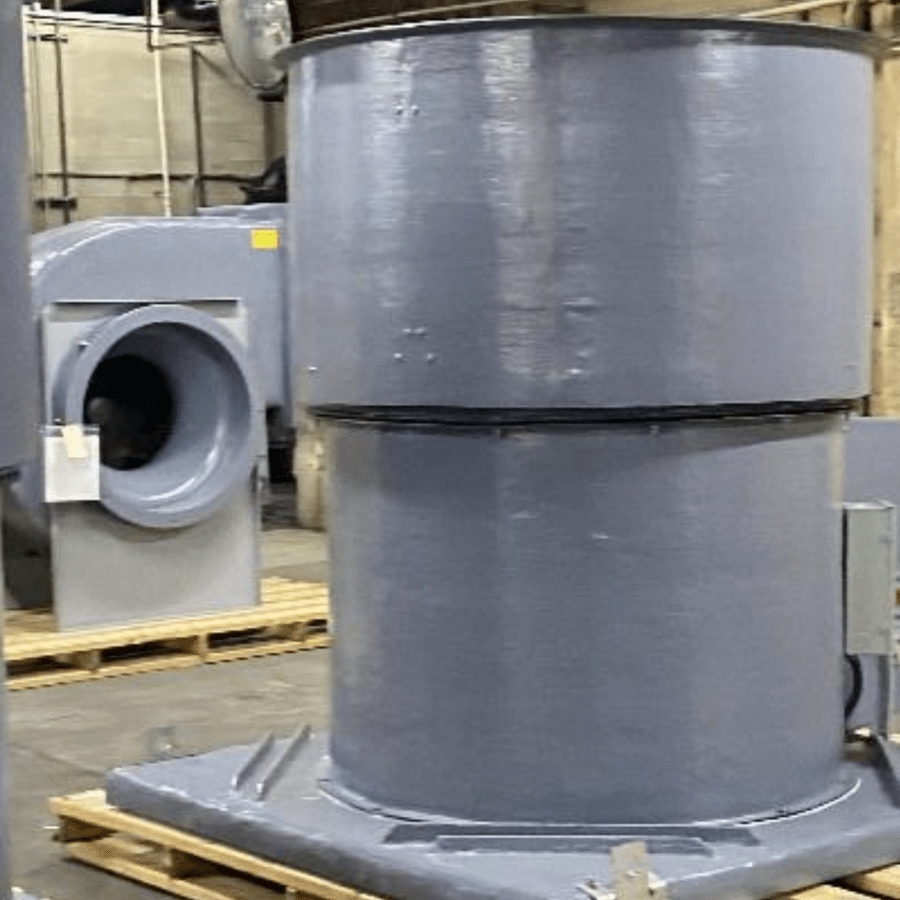

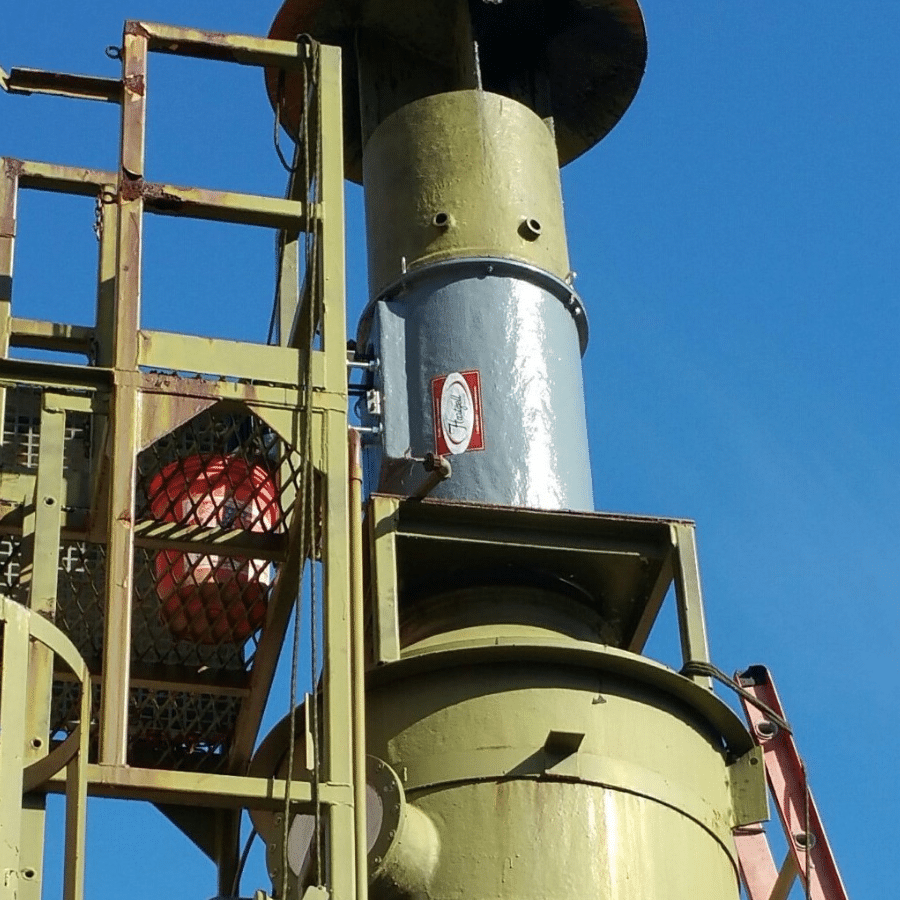

Fiberglass Fans

Fiberglass (FRP) fans and blower designs are long-lasting, lightweight, and moisture resistant. They are best utilized in scenarios where corrosive elements are in vapor form. FRP is not impacted by low temperatures, has low maintenance requirements, and has a high strength-to-weight ratio. Both general ventilation and process fans are available for large-area ventilation or directly coupled for process machine exhaust. They are manufactured in a single perfectly molded piece, with airfoil blades not joined from multiple parts, making them highly efficient and capable of long-term service.

General Ventilation Fans

General ventilation FRP fiberglass fans are lightweight, dimensionally stable, and feature high strength-to-weight ratios. They are utilized in areas with high concentrations of corrosive fumes and vapors. Water and wastewater plants utilize these fans for room and building ventilation, either in exhaust or supply mode. Examples include:

- Fiberglass Upblast and dome exhausters

- Fiberglass wall ventilators

- Fiberglass upblast and hooded roof ventilators

Process Ventilation Fans

Axial

Fiberglass axial fans are used for direct exhaust applications such as wet well exhausts, where metal fans become impractical in handling corrosives in the airstream. The one-piece manufacturing of FRP fans will reduce the need for multiple replacements and eliminate system downtime due to fan failure. These fans are available in FRP duct fans, FRP duct axial fans, and FRP bypass fans.

- Fiberglass duct fans

- Fiberglass Duct Axial Fans

- Fiberglass Bypass Fans

Centrifugal

Centrifugal fiberglass fans, like their metal counterparts, are designed for high-pressure applications. They handle corrosive airstreams well and are highly efficient and designed with low-noise features and non-overloading performance. The fan wheel is a one-piece molded design with airfoil blades for efficiency and long life. They are available as:

- Backward curved centrifugal fans

- Fiberglass radial blowers

- Fiberglass inline centrifugal fans

- FRP Pressure Blowers

Marine Duty Fans

Marine duty fans are utilized on ocean going vessels such as container ships, bulk carriers, general cargo ships, passenger ships, and oil and product tankers. These marine duty fans are designed for long life, low maintenance, corrosion resistance, and reliability. Marine environments are often severe, and these fan designs are reflected as such in their heavy-duty construction and certifications. Design types include:

- Marine Duct Axial

- Marine Centrifugal

- Marine Vaneaxial Blowers

OEM Fans & Blowers

OEM stands for original equipment manufacturers, where an axial or centrifugal fan or blower is modified to fit within the design of a client’s equipment. The reliability of these fans is extremely important to the OEM. With years of OEM application experience, SysTech will assist you in fitting fans and blowers into your equipment. Examples of modifiable fans include:

- Duct fans

- Plug fans

- Plenum fans

- DWDI fans

- Square centrifugal fans

- Bin vent fans

- Pressure blowers