SysTech, employing the Donaldson pleated filter, has been able to help many baghouse clients with pleated filter upgrades to increase the period between filter element changeout, improve filtration efficiency and increase dust collector capacity. Minimized maintenance staffing seems to be everywhere, so reduced maintenance in your baghouse is a no-brainer.

Here are the top 6 reasons our customers choose to use pleated bag filters:

1. More filter area – pleated filters have 2-3 times more filter area than bags. Pleated filters will allow more airflow which you will need if you are expanding your dust collection system or are already overloading your present dust collector. The capability for more airflow using the same collector and possibly the same fan is a plus!

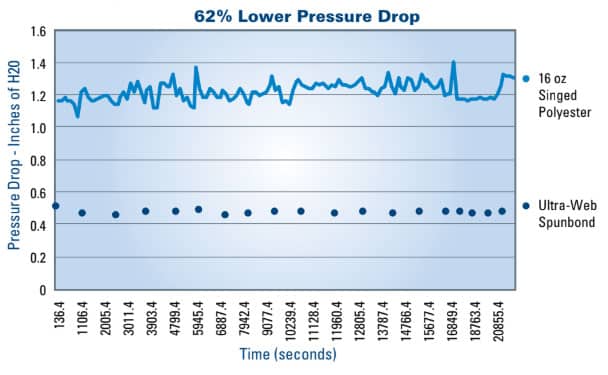

2. Lower pressure drop across your filters – System pressure increases as filter media gets loaded with particulate and airflow is reduced. Periodically the bags are cleaned by pneumatic means, but if the filter media cannot be cleaned or refreshed, resistance to flow occurs and pressure increases. More pressure and less airflow result in reduced capture of dust at a hood or machine and dust settling in the ductwork.

With efficient filter media at design airflow, and the correct amount of filter media in the dust collector, less horsepower is required.

During a six hour performance test, Ultra-Web Spunbond ran at a lower pressure drop than the 16 oz polyester felt. The average pressure drop for Ultra-Web Spunbond was 62% lower than singed felt.

3. No abrasion or tears on you filters – Baghouse designers have always packed the maximum amount of filter media into the dust collector box to keep it as small as possible. Should the particulate be abrasive, filter media deterioration and leakage may develop as the collected particulate blasts into the filter bags. If filter bags are failing, the shorter length of pleated filters affords a larger dropout area, and the direct impact of abrasive particulates on the filters is reduced.

4. No Stack Discharge – overloaded and abraded filters can cause dust clouds when collectors pulse clean or backflush.

5. Longer filter life – 2 to 3 times the filter life if we compare pleated filter element to a bag. Extending the period between filter bag changeouts is always a plus!

6. Expense of labor to changeout filters – When you need to change filters, either from the original bag or a pleated filter, Donaldson Pleated Bags have been designed specifically for a quick and easy procedure. The hassle of changing bags and cages is in the past.

Cut down on man-hours considerably by using Pleated Bag Filters. An easy to replace design, as well as the additional filter life, means your employees can focus on other tasks.

SysTech has used pleated bags successfully in many applications. A lot of the requests are for difficult applications where airstreams contain water, oils, detergents and other constituents that adhere to the filter media and make it near impossible to remove the collected particulate. Optional hydrophobic and oleophobic coatings are available for the Donaldson Pleated Bags to address those issues.

Call us and let us see what we can do for you.

Some of our solutions can be found in our case studies:

Foundry Extends Baghouse Life by a Factor of 6

Pleated Filter Bags for Abrasive Food Dusts

Baghouse Retrofit Using the Latest Filter Bag Technology