Explosion Isolation

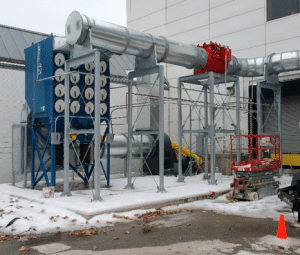

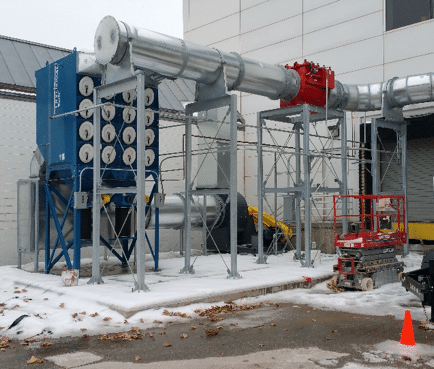

In the event of an explosion, it is imperative that the event is isolated from the rest of the process system network to prevent secondary explosions.

When we propose explosion isolation we mean encapsulating an explosion within a process vessel, perhaps a dust collector, and preventing a fireball from exiting that vessel or isolating it from the associated process equipment and duct.

Complete explosion isolation systems are comprised of components that are designed to detect a combustible dust explosion as soon as it occurs and to instantly isolate or contain the deflagration and prevent it from spreading back through the duct system into the facility.

Combustible dust explosions are classified as primary and secondary. Initially, we apply various means of explosion protection for process equipment, the known combustible dust generators, but secondary explosions potentially have a more dangerous result when the deflagration fireball migrates back thru the exhaust duct to interconnected process equipment and igniting accumulated dust off horizontal surfaces or secondary “dust clouds” created by the initial explosion. Because secondary dust sources are not containable and if your dust has been tested and poses a risk, isolation is mandatory to include in your explosion protection program. That said, good housekeeping along with knowledge of and removal of accumulated dust will significantly mitigate this potential problem. If you have an explosion component on your process equipment, don’t misunderstand the risks of not having isolation on that same system, i.e. an explosion vent on your dust collector does not protect you against a possible secondary dust explosion catastrophe.

Explosion isolation is mandated by NFPA Standard 654: Standard for the Prevention of Fire and Explosion from the Manufacturing, Processing, and Handling of Combustible Particulate Solids.

Explosion isolation devices are defined as active or passive. Active devices need a detection device to sense pressure increase and signal the isolation device to actuate. Passive isolation devices or flap valves are fully operational with airflow and close shut in reaction to a deflagration pressure increase. There are four types of explosion isolation devices IEP Technologies and SysTech offer based on the Kst and Pmax of the dust:

Explosion Isolation Flap Valves

IEP Technologies Inc. (IEP) offers several models of explosion isolation devices, including an IsoFlap™-M flap valve and the Ventex isolation flap valve.

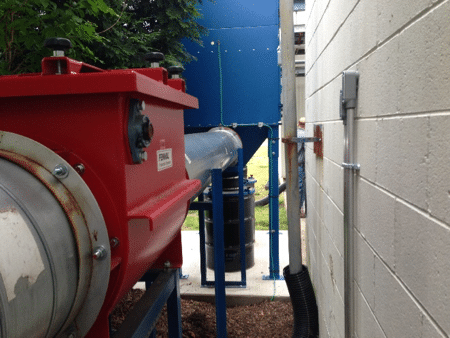

The IsoFlap™-M valve, a passive isolation flap device, is a reliable explosion isolation solution that mitigates explosion propagation risks to upstream equipment. The IsoFlap™–M by IEP Technologies Inc. is available from 4 to 28 inches diameter and meets the requirements of OSHA Combustible Directive and NFPA 654, 69 latest edition, and EU ATEX directive compliant.

If returning the cleaned exhaust airstream to the facility, an IEP Technologies “VENTEX” passive isolation valve may be applied, depending upon your system design. Ventex valves are available for applications in dust transport systems for dust explosion Classes ST-1 and ST-2.

IsoFlap™-M Isolation Flap valve

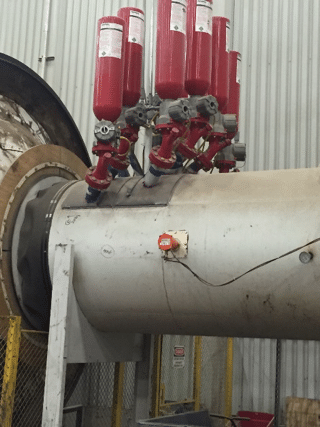

Chemical Explosion Isolation

A bottle charged with sodium bicarbonate discharges an explosion suppressant into the duct to suppress a fireball, preventing it from reaching inter-connected equipment or plant areas. As an active device, it is activated by a signal from a Dynamic Rate of Rise pressure detector through a control and monitor panel. They are applied where Kst dust values are very high, or duct diameters are very large or as part of a complete dust collector suppression package.

Chemical Explosion Isolation Bottle

High-Speed Explosion Isolation Valve

High-pressure explosion isolation valves are activated when a pressure detector senses the pressure wave from the deflagration and triggers the release of a high-speed knife gate to close, forming a mechanical barrier in the pipeline. The barrier prevents propagation of the fireball back into the interconnecting duct and processes; isolating and protecting the return air duct from a secondary explosion. High-speed valves are an active device, and a control panel and pressure detector are required as part of the package.

Mechanical “Knife Gate” Isolation Valve

Hopper Explosion Isolation

Dust collector designs typically incorporate a Rotary Airlock Valve at the hopper outlet to provide an air seal as the collected particulate is discharged into a dumpster or another collection device. When handling potentially explosive materials, isolation at the outlet of the discharge hopper of a dust collector requires an isolation flame barrier to meet NFPA Code. If a rotary airlock is used, it must be designed for the pressures associated with a deflagration. SysTech installs rotary airlock valves that are tested and certified to comply with NFPA 69.

A second outlet option is a Drum Kit. The XP Products drum kit is attached to the hopper outlet, it acts as an extension of the dust collector hopper. The drum kit, which is a passive solution to combustible dust protection, includes a spool piece that bolts to the hopper outlet, a hydraulic lift rated to 800 pounds, and a drum band clamp. The hydraulic lift makes moving of the filled drum much easier and less strenuous on the operator. The kit meets NFPA compliant 3rd party testing to 14 psi. A dust level sensor is available as an option.

Donaldson Torit offers an SDK option that is a tested and NFPA compliant connector piece between the hopper outlet and a 55-gallon drum.

Whichever explosion protection components are installed it is important to remember periodic inspections are required per NFPA Code. Refer to the applicable NFPA Code or ask us at SysTech and we’ll give you the information you need to be sure you’re covered.

All IEP explosion isolation systems and components are highly effective in preventing explosions from igniting and creating secondary explosions in associated equipment or adjacent work areas. SysTech, with IEP’s engineering knowledge, will assist you in designing and installing explosion isolation components as part of your complete explosion protection system.

Rotary Airlock Valve

XP Products Hopper Isolation