Combustible Dust Testing

Dust explosion threats are a crucial concern in today’s industrial environments. The cost of dust explosion damage amounts to millions of dollars each year. Of greater concern are the lives that might be lost. If you suspect you are at risk, have your dust tested. The latest NFPA Standards, particularly NFPA 652, require a documented DHA (Dust Hazard Analysis) to be on file with your AHJ (authority having jurisdiction). We can help you with that.

The management of combustible dust is mandated by safety legislation and regulatory codes. NFPA 69 and 652 Standards cover the design, construction, operation, maintenance and testing of systems for the prevention of deflagration explosions by means of the following methods: (a) control of oxidant concentration; (b) control of combustible concentration; (c) explosion suppression; (d) deflagration pressure containment; (e) spark extinguishing systems. Employing the use of an effective combustible dust removal and explosion protection system will not only protect your workers, facility, and assets but will ensure your operation is in compliance with all of the safety laws concerning combustible dust and dust explosions.

Why do You Need to Test Your Dust?

You need to test your dust for several reasons. First, do you have a potential explosion on your hands? You need to know that. Second, if your facility is governed in any way by NFPA 652 through local Codes, insurance carriers, safety personnel, then you are required to do so. And lastly, you want to protect your people and your facility.

It’s not uncommon to move a dust collector to a new application, and because you see explosion vents or suppression systems attached to the collector, you might believe you’re in good shape. Not necessarily, not without testing the new dust. Remember, identical dust chemistry does not dictate the same Kst or explosivity value. Particle size, distribution, and process changes are all contributors as well.

If you do not know the potential hazard of your dust, you need to get it tested. An Explosibility Screening Test or “Go / No-Go Test” is the first step. If necessary, additional testing can include:

- Dust Cloud Reactivity (Pmax and Kst)

- Dust cloud Minimum Ignition Temperature

- Dust Layer Ignition Temperature

- Dust Cloud Minimum Ignition Energy

- Minimum Explosion Dust Concentration

- Minimum Safe Oxygen Concentration

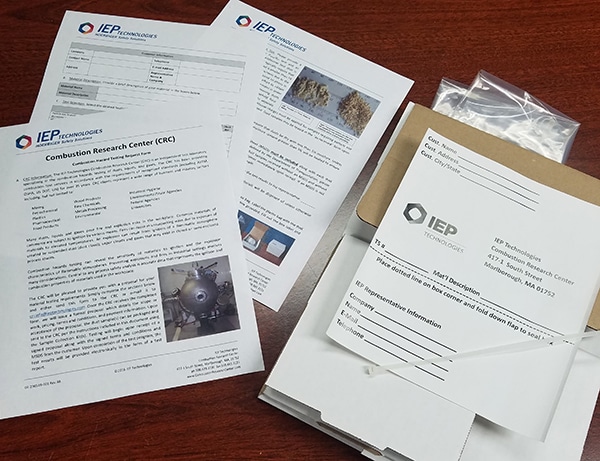

- Combustion Research Center (CRC), a division of the HOERBIGER Safety Solutions Group, is an independent laboratory that performs testing of combustion hazards including dust, liquids, and gases.

Other Divisions of HOERBIGER Safety Solutions Group have extensive expertise and experience in developing systems to deal with the hazards of combustible dust. They provide a wide range of resources including:

- Large database cataloging combustible dust, liquids, and gases.

- Products offered by other HOERBIGER Safety Solutions Group – Suppression system components, explosion vents, and isolation valves

- Comprehensive staffing – they have the field engineers, designers, customer service, service technicians and trainers needed to protect your operations

- Worldwide Service – Authorized IEP Technologies Service Centers throughout the world

SysTech is ready to discuss your combustible dust containment and removal needs.