Acoustic Flexible Connectors

Industrial acoustic flexible connections (or acoustic expansion joints) are designed to address vibration isolation and breakout noise attenuation; conventional HVAC flex connectors or flex joints are inserted for vibration, not for noise attenuation.

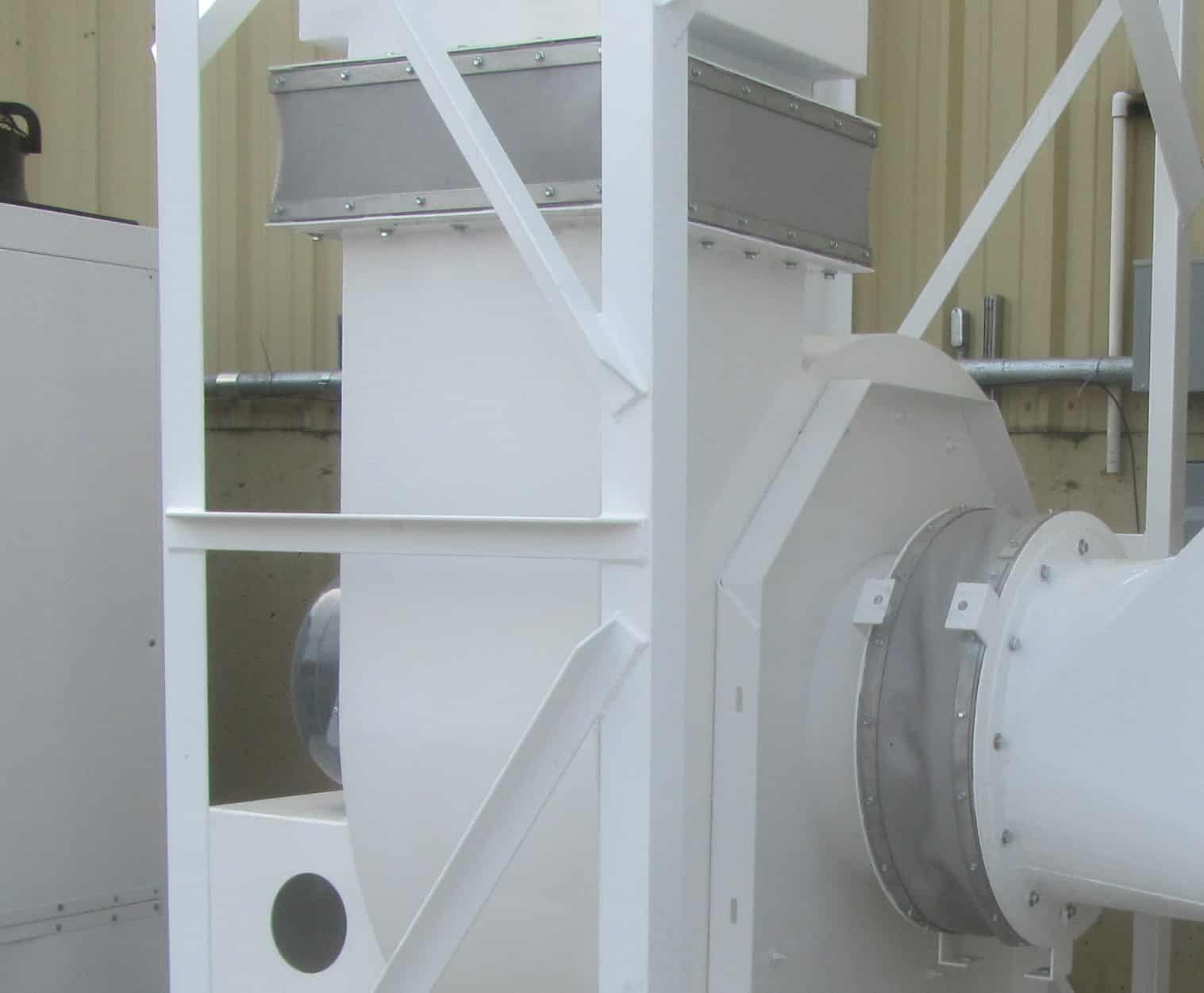

When industrial duct systems are installed, an air mover is typically part of the design. Air movers, such as a stand-alone fan or a fan integral to a dust collector, air handling unit, or process equipment, can produce objectionable noise. This noise is typically addressed with an inlet or an outlet silencer.

An often-neglected noise source is the breakout noise from the inlet or outlet flexible connectors which connects the duct to the silencer, fan to the silencer, or dust collector/process vessel to the duct system.

Acoustic flexible connections (or acoustic expansion joints) are manufactured using a unique combination of materials to control airstream breakout noise. Depending on the application, the flexible inner wall is manufactured from EPDM or high-temperature PTFE; acoustic media of fiberglass or mineral wool is then sandwiched between this inner wall and a tough outer acoustic barrier. Finally, everything is secured in place with two sets of heavy-duty backing bars.

All of our flexible acoustic connections are acoustically rated with predictable and guaranteed noise attenuation levels. Depending on the fan noise spectrum, attenuation can be as high as 30 dBA.

Example Acoustic Flex Connector Selection

Attached is an example computer selection result for sizing an acoustic connector. The input data was taken from the fan manufacturer’s Fan Sound data sheets and entered into the selection program. The sound pressure at the fan outlet at 3 feet was 88 dBA.

When the flex connector was added to the fan outlet, the attenuation results were as follows: sound level through the EPDM flex was 86 dBA, and when a flow liner was added, 73 dBA. The flow liner provides attenuation and is advantageous when abrasive materials are in the airstream. When the acoustic treatment was added (pillow block), the sound level was 67 dBA. In our example, we asked for a 70 dBA level at 3 feet.

SysTech can make an acoustic flex connector selection for your project, but first, we require some particulars. The attached Flex Connector Questionnaire addresses requisite information that allows us to generate a preliminary selection, or, if we have all the necessary data, a final cost estimate. In some cases, information may not be known, but please provide us with as much detail as possible.

For easy installation, our acoustic flexible connections are provided with pre-drilled flanges custom cut to match any existing connections. These flanges are backed with weld nuts and fitted with proprietary shipping braces that hold the unit to its proper length during installation.

Our ventilation systems usually have a noise component that needs to be addressed. If it’s fan noise, call us to see if a flexible acoustic flexible connector will alleviate the issue.

Acoustic Flexible Connectors

An Integral Part of an Industrial Ventilation System

Integrated industrial ventilation systems where fan noise is a contributor to overall plant noise, will incorporate flexible acoustical connectors on fan and blower inlets and outlets to minimize breakout noise from commercial-grade flex joints