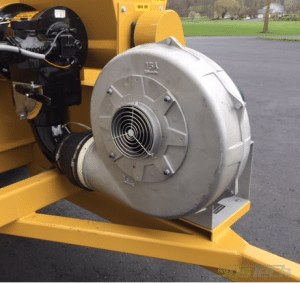

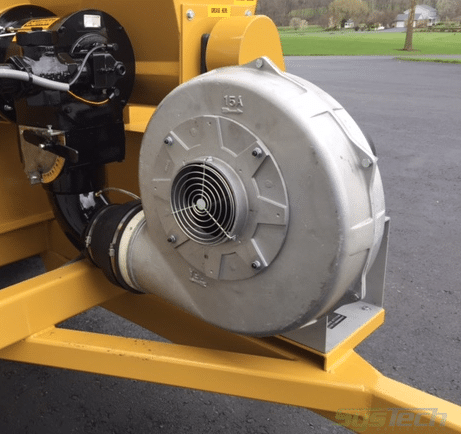

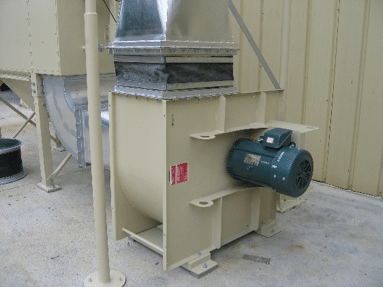

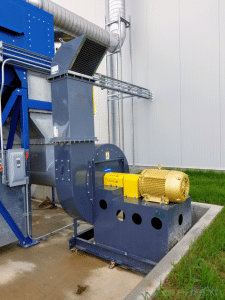

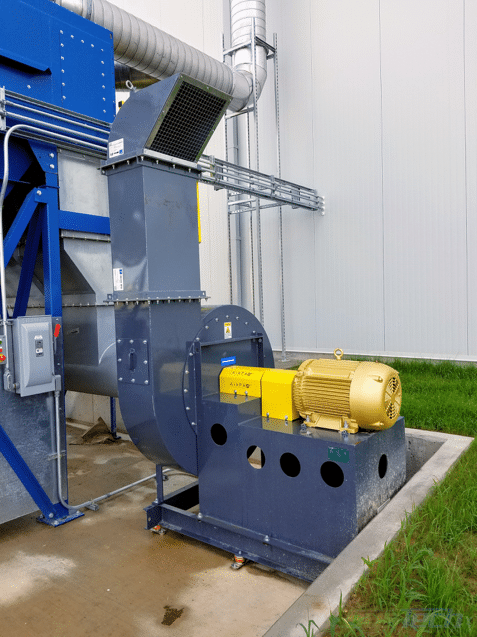

Centrifugal Fans and Blowers

Centrifugal fans employ the use of a rotating impeller or wheel to increase the speed and pressure of an air stream. Air is discharged at 90 degrees to the inlet airstream. The centrifugal speed increases as the air stream reaches the ends of the fan blades and is then converted to pressure. Centrifugal fans develop much higher pressures than axial fans and are widely used for industrial processes because of their ability to handle particulate and aggressive chemistry in the airstream. They are categorized by their wheel designs, materials of construction and configurations. Wheels can be airfoil, radial or backwardly inclined designs and in carbon steel, stainless steel or FRP construction and their configuration will determine if they are cataloged as a high-pressure blower, plug fan, square fan, or industrial exhauster.

Optional wheel designs produce differing pressure ranges and CFM possibilities, efficiencies vary and generated noise levels fluctuate. Some degree of noise attenuation is typically required for an industrial centrifugal fan. Read about centrifugal fan noise attenuation here.

These fans are able to produce high pressures and are suitable for harsh operating conditions, such as:

- Systems with high temperatures

- Moist or dirty air streams

- Material handling/conveying

Fan Wheels for Difficult Airstreams

- Backwardly Inclined – Seen on dust collector fans, some light dust acceptable

- Backwardly Curved – Industrial applications with improved efficiency

- Airfoil- Clean air fan wheel with high efficiency

- Open Radial – Heavy material handling

- Closed Radial – Heavy material handling

- Radial Tip – Material handling

- Forward Curved – Clean air, low pressure wheel

- Double Width Wheels – Double the airflow

Specialty Fan Designs

- Plug Fan

- Paper Trim “Chopper” Fan

- “Swing-out” Fan

- In-line Centrifugal Fan

- Turbo Pressure Blower

- Square Fan

- Flange mounted Fan

- OEM Designs

- FRP & PVC Construction

- High Temperature Fans

Centrifugal Fan and Blower Configurations and Accessories

- Drive Arrangements 1, 2, 3, 4, 4HM, 7 , 8, 9, 10

- Materials of Construction – Carbon steel, stainless steel and food grade SS

- Dampers

- Inlet Filters

- Inlet Boxes

- Expansion Joints

- Unitary Bases

- Split housings

- Temperature and Vibration sensors

- Cladding for heat and/or noise

- “swing-out” impellers

The SysTech experts are ready to discuss your centrifugal fan needs.