The capture of fumes, smoke, gases, dust, or contaminated ambient air cannot always be effectively accomplished using fixed duct exhaust systems or remote room air recirculation/filtration make-up air units. The point of capture may change rapidly, the contaminant source might be in a tight inaccessible space, the workpiece or assembly may be too large to encapsulate, or a fixed hooded system gets in the way of productivity. For these applications, an extraction arm is the best choice as they are adjustable, movable, and fixed into position.

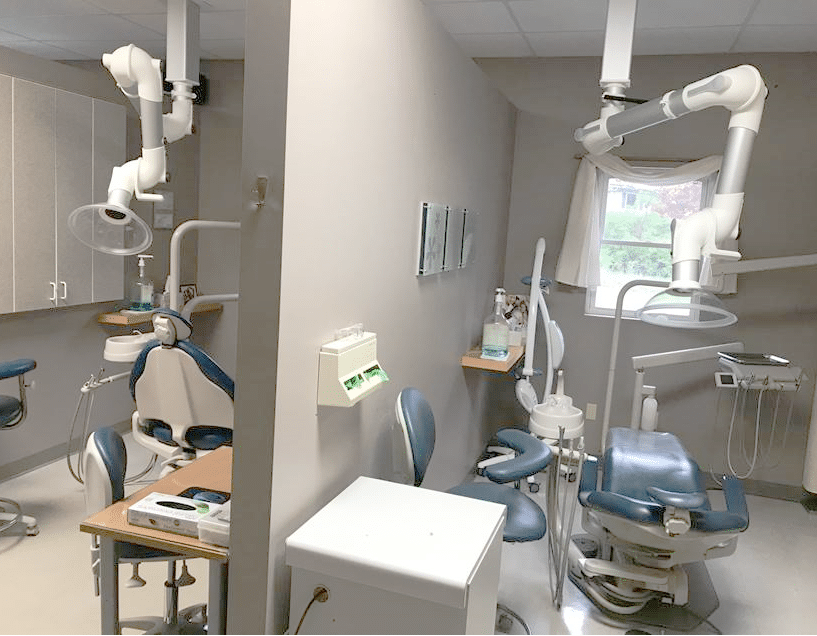

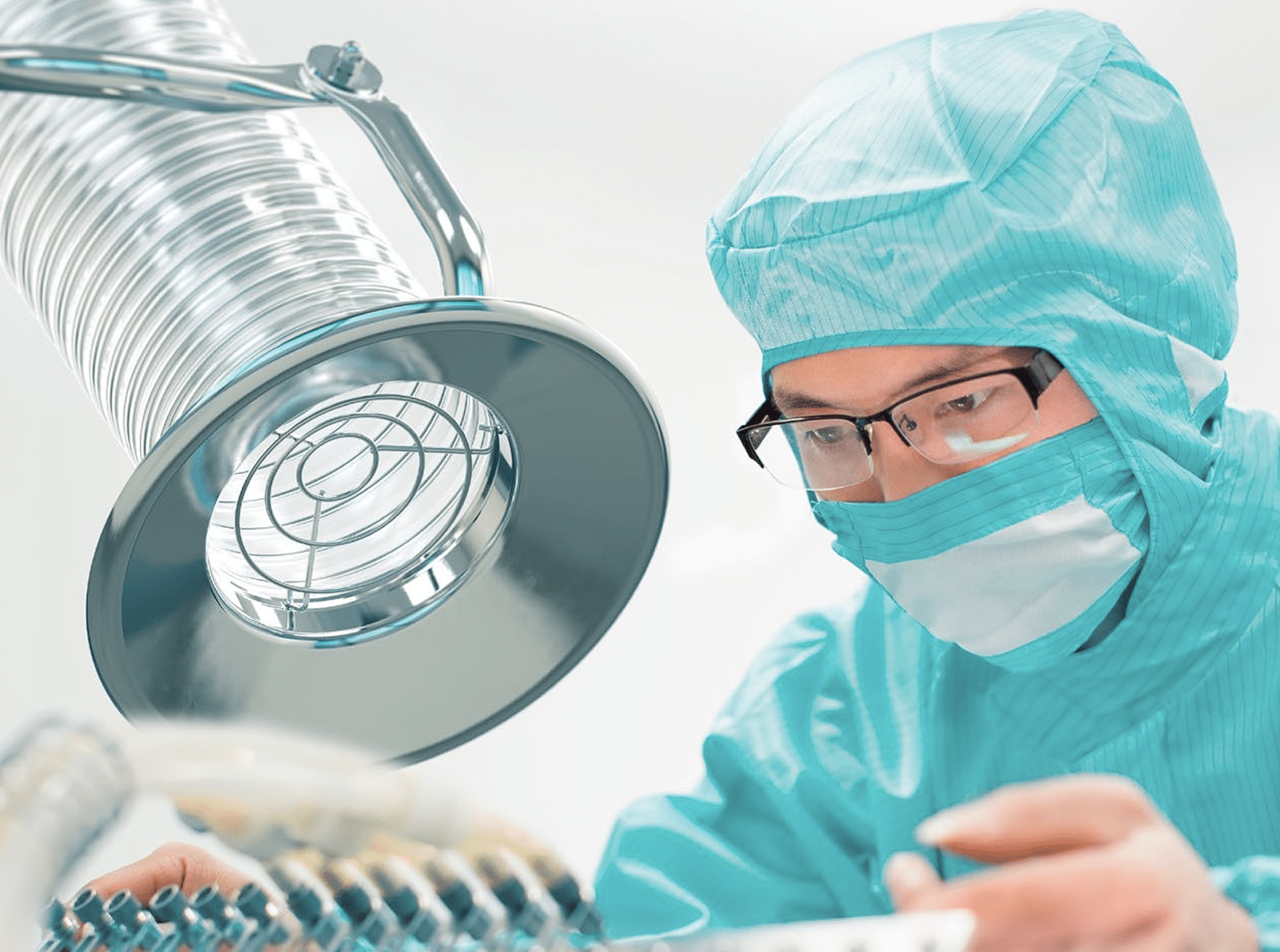

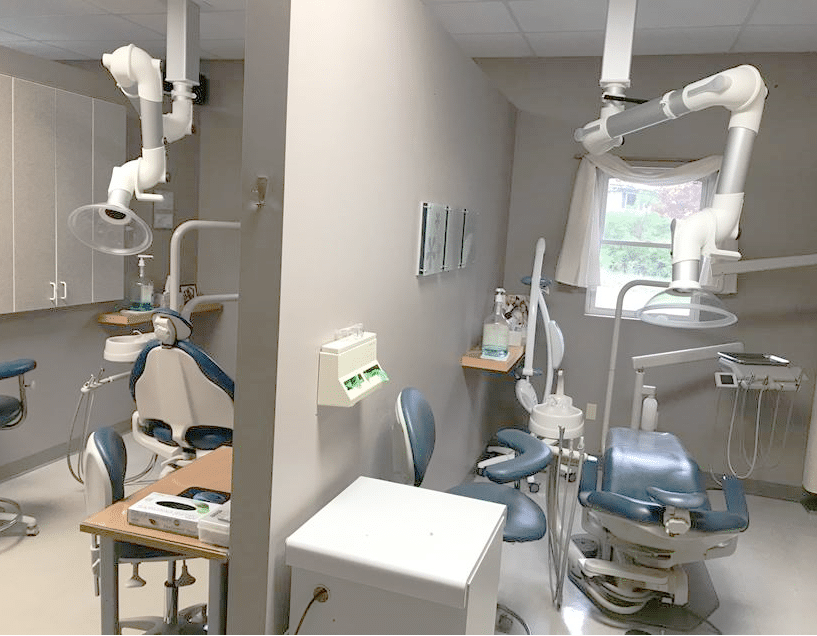

In the health care environments where close contact is often necessary, source capture of airborne pathogens before they are dispersed into the local environment is mandatory. Utilizing extraction arms is one step to be considered as a stand-alone or investigated as an add-on to a ventilation system to mitigate the spread of infectious aerosols, toxic gases, odors, and particulates.

Extraction arms are available in most metals and plastics for abrasive, chemically aggressive, and explosive environments, with industry-specific designs such as cleanrooms and food applications where quick disassembly features are essential for maintenance and hygienic cleaning.

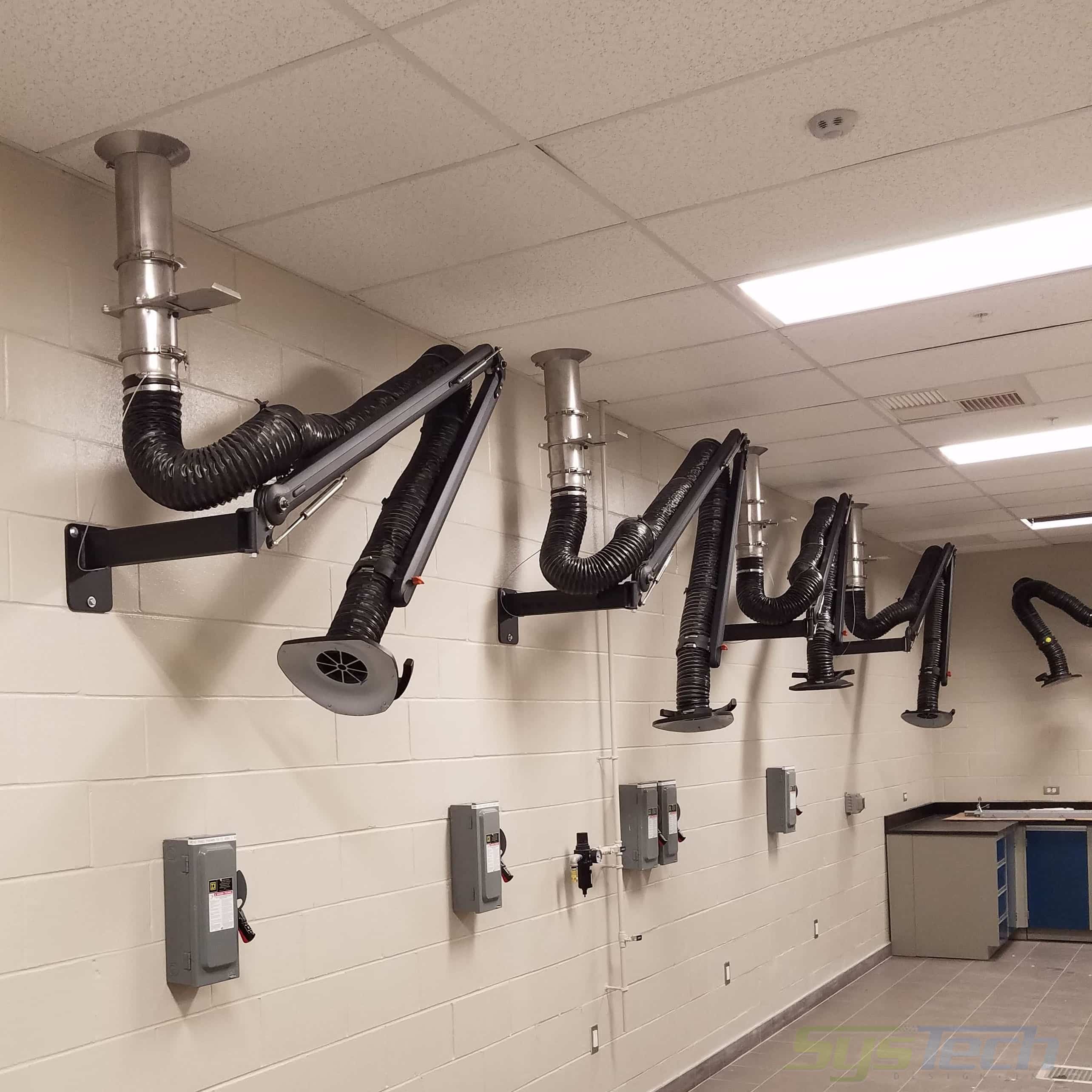

Industrial Extraction Arms

What is an Extraction Arm?

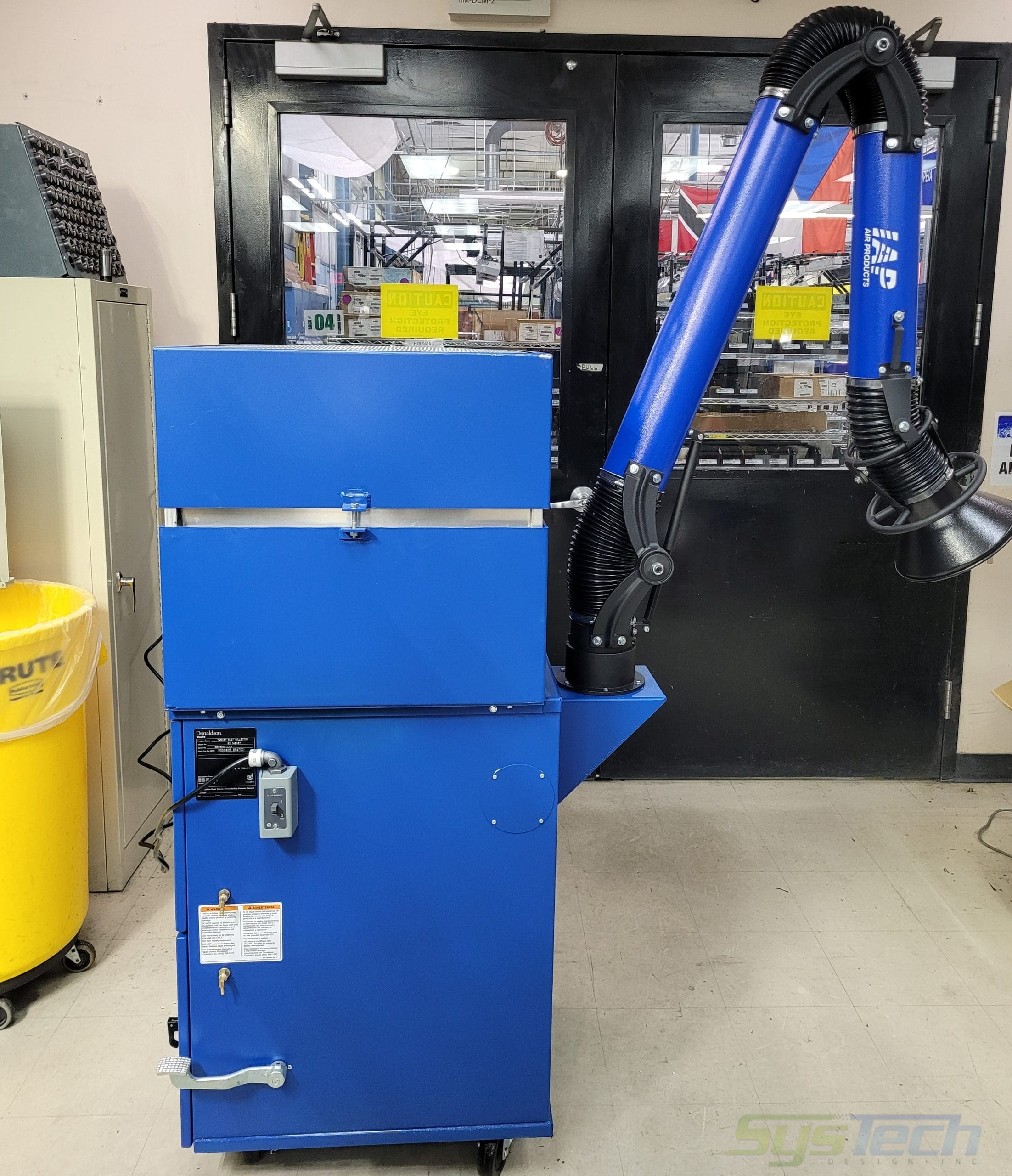

An extraction arm is called by many names including flex arm, weld fume extractor, laboratory fume extractor, fume arm, flexible fume collector, weld smoke extractor, articulating arm, boom arm, fume extractor, and just plain extractor. They are typically coupled with a duct or dust system to collect a “contaminate” or pollutant at its source.

These “arms” are comprised of a hose of optional diameters, a rigid member (s) such as a rod or tube, either on the inside or outside of the flex and trunk. There are sections of pipe along the hose, booms to extend the reach of the arm, dampers, hoods, lights, switches for a fan, and a fan or exhauster. Extraction arms are selected for the airstream temperatures and constituents, explosive materials, oils, etc. Many of the explosion rated designs come with ATEX approval, having been checked, tested, and approved for use in those rated spaces.

Arms are rated by airflow and the amount of static pressure loss when used in an extended or retracted position. They have an extended work radius or reach option, but it will cost in static resistance and horsepower. Where applicable and used responsibly, they are an invaluable tool for a clean air solution.

SysTech can make an extraction arm selection for your project, but first, we require some particulars. The attached Extraction Arm Questionnaire addresses requisite information that allows us to generate a preliminary selection, or, if we have all the necessary data, a final cost estimate. In some cases, information may not be known, but please provide us with as much detail as possible.

What is Source Capture?

Source capture is a ventilation design option where the collection of a particulate, fume, odor, mist, or airborne pathogen is at its’ source and a hood on the extraction arm is positioned close to the source of the contamination. There are optional hood designs available to maximize collection efficiency while minimizing interference to the work procedure or operation.

Importantly, the arm allows movement of the hood to a neutral position when access to a source is required. When used in a ventilation system, source capture removes the minimal amount of air to capture a contaminate, thus requiring the minimal amount of make-up air to be brought in to balance the building pressure. If air filtration is part of the ventilation design, smaller amounts of air require less air filter capacity.

To maximize capture efficiency, flexible extraction arms with specialty hoods are the best solution available. They have extended reach or can be easily repositioned and moved out of the way to save space. The goal with an extraction arm is to capture as much contamination as possible within the positioning, workflow, and operatory procedure constraints.

Source Capture Ventilation Using Extraction Arms

Source capture using extraction arms is a ventilation option often used for control of particulates, gases, and mists. It is not a 100% effective capture efficiency but where fixed systems cannot be used it is the best available option for many applications. The collection efficiency of the hood/arm is predicated on several factors such as CFM, positioning, distance from the source, room air movement, and temperature as examples. Locations, where exhaust systems using extraction arms are frequently applied, are:

Industrial Fume and Dust Extraction – Industrial use of extraction arms includes the capture of powder, dust, smoke, fume, and mist from a broad range of processes. The mechanical flexibility of the arm and the ease of movement make source capture by this means, a preferred option for control of isolated sources.

Weld Fume Extraction – Exhaust arms are a staple in this industry because of their flexibility. Weld and assembly projects can be small benchtop or very large and the moveable extraction arm allows the best available smoke and fume collection.

Laboratories – Many chemical and biological analyses often need multiple source capture points and the extraction arm provides the movability to meet those requirements.

Food & Cleanroom Environments – Industries with strict hygiene requirements require stainless steel, easy-to-clean extraction arms to ensure the safety and quality of their products.

Dental Office Airborne Pathogen Exhaust – The close contact of the patient to professional allows the hood and arm functionality to get close to the dental procedure without inhibiting the work.